Repair

309518P 25

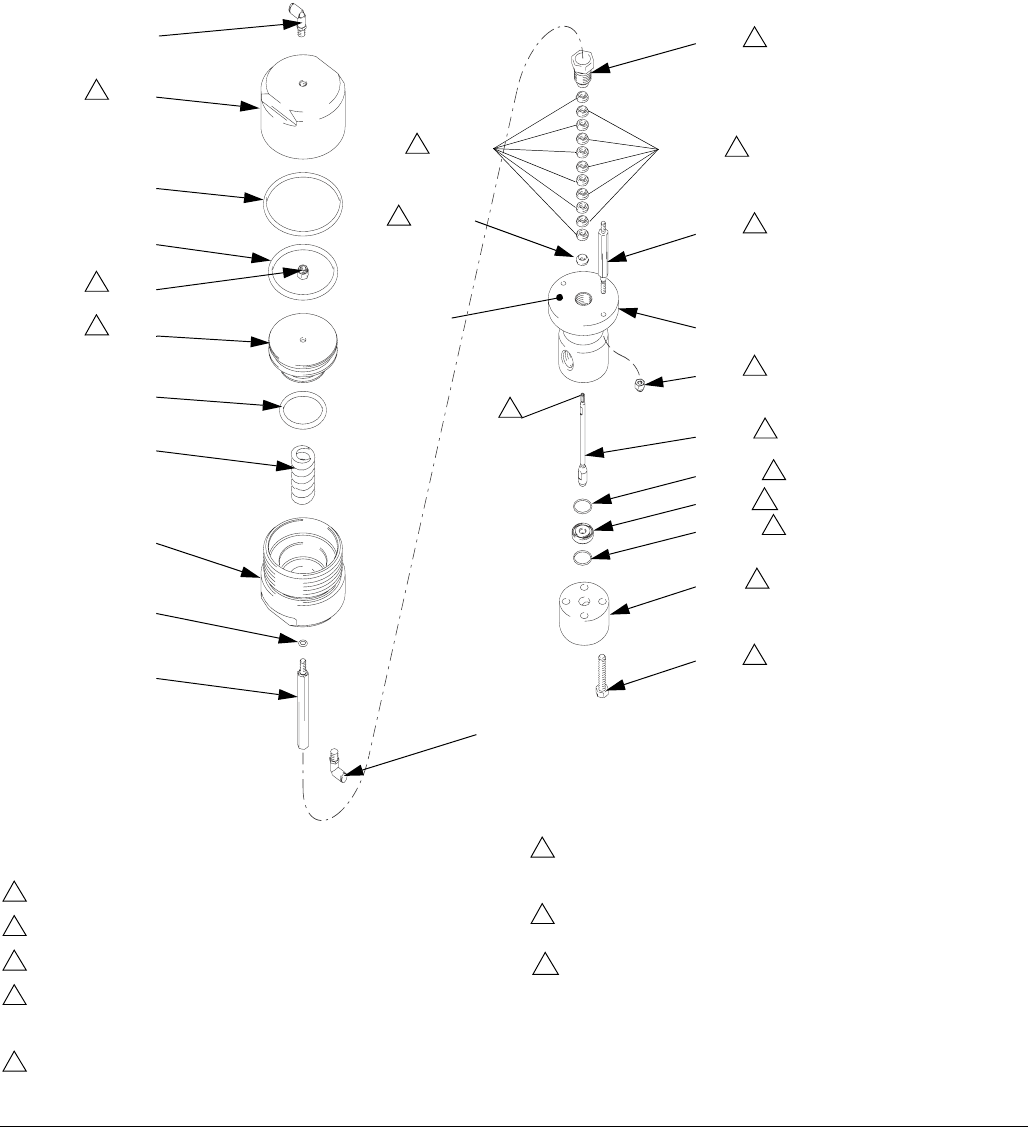

FIG. 20

627

639*†

*† 637

626

*† 638

628

630†

645*†

644†

645*†

646

647

621

621

622

*

† 632

631

623

*† 633

† 635

624

*† 643

625

629

636

1. Apply pipe sealant to non-swiveling pipe threads.

2. Apply lubricant to threads, o-rings, and seals.

Apply medium anaerobic adhesive. Thread to bottom.

Torque to 5-7 ft/lbs (7-9 N•m).

Torque to 30-40 ft/lbs (41-54 N•m).

Tighten packing nut 1/4 turn after nut bottoms out; 145-155 in/lbs

(16-18 N•m). Check packing nut tightness about once a month.

Keep packing nut filled with TSL.

Lubricate and press piston evenly into cylinder.

Clean needle (630) and packing cavity before reinstalling

packings (637*, 638, 639*). Lubricate packings and install with

lips facing up toward packing nut (627) in order shown.

Whenever the seat housing (646) is removed, replace the o-rings

(645).

Inspect reversible seat for damage. If one side is worn, reverse

seat.

3

4

5

6

7

8

9

10

4

5

4

6

3

4

7

8

8

8

*† 634

8

9

9

10

9

5