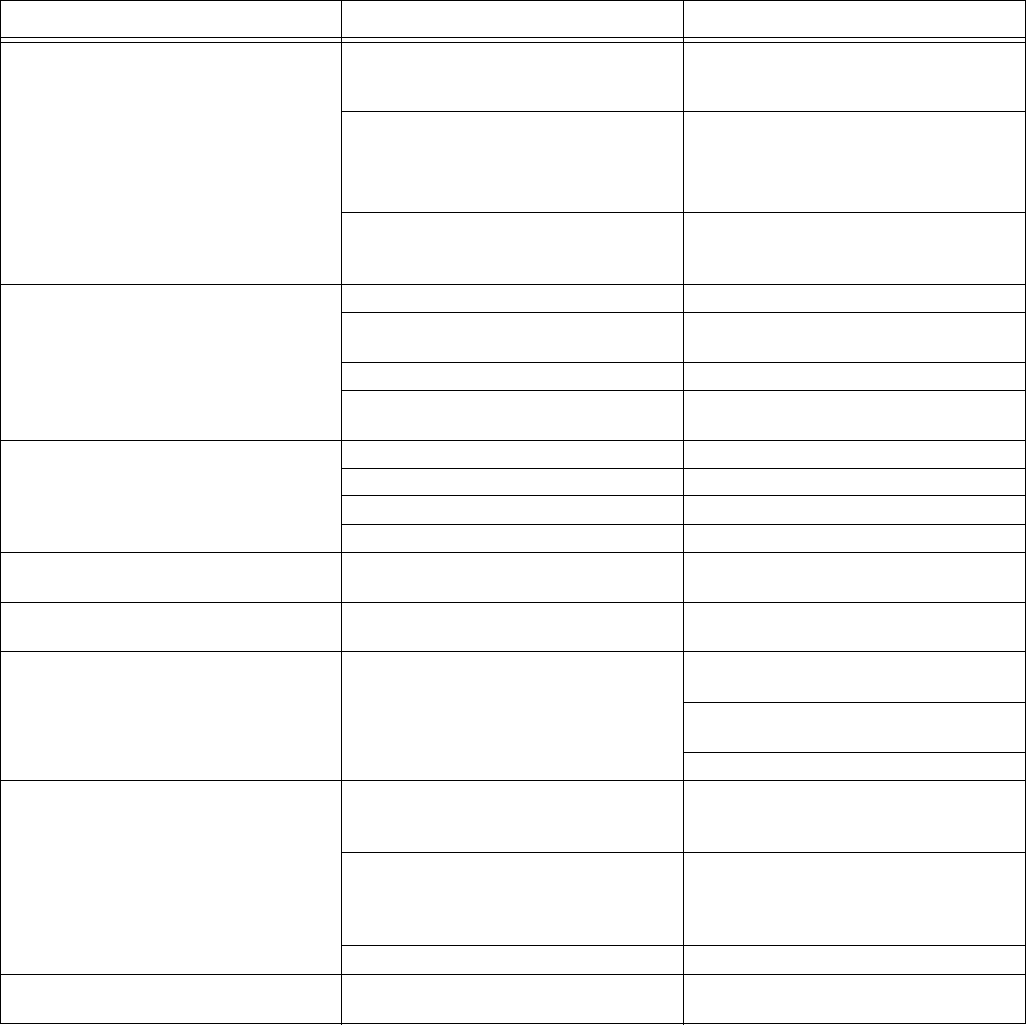

Troubleshooting

309518P 13

Paint does not cure consistently. Ratio not set correctly. Check that correct ratio is set and set by

volume. See Xtreme Mix Operation man-

ual.

Material not mixing correctly. Test pump. Page 10.

Make sure mixer is clean; flush as

needed. See Xtreme Mix Operation man-

ual.

Pump not operating correctly. Observe whether pumps are loading and

checking correctly, if not, clean and repair

pump. See pump manual.

Poor spray pattern. Fluid pressure too low. Increase pump pressure.

Spray tip dirty or worn. Relieve pressure. Clean or replace tip.

Follow gun manual instructions.

Fluid A or B filters plugged. Clean filters. See pump manual.

Mixer or hoses partially plugged or too

restrictive.

Inspect parts for cured material. Clean or

replace, or use larger hoses and mixer.

System runs erratically. Air filter(s) clogged. Replace elements. Clean. Replace element(s). See page 16.

Air supply hoses undersized. Replace hoses with appropriate size.

Air compressor undersized. Use larger air compressor.

Air supply pressure tank undersized. Use larger pressure tank.

Air supply relief valve opens. Turbine air regulator set too high. Lower setting to 23-25 psi (172-241 kPa,

1.7-2.4 bar).

Turbine alternator makes high-pitched

whining noise.

Turbine bearings worn. (Setting turbine

air regulator too high, wears bearings.)

Replace bearings. Page 20.

Display shows 88888 or unit reboots

unexpectedly.

Turbine is not supplying enough power to

board.

Increase turbine regulator setting to

23-25 psi (172-241 kPa, 1.7-2.4 bar).

Check turbine and electrical control

exhaust air for restrictions.

Replace turbine bearings. Page 20.

Xtreme Mix does not start when start but-

ton is pressed.

Faulty start switch or wire harness. Check start switch and wiring harness

continuity; switch is normally open circuit.

See Electrical Schematic, page 28.

Faulty stop switch or wiring harness. Check stop switch and wiring harness

continuity; stop switch is normally closed

circuit. See Electrical Schematic, page

28.

Bad I/O port on main board. Replace board. Page 17.

Fluid valves leaking. Loose or worn packings. Tighten packing nut. If leak continues,

replace packings. Page 24.

Problem Cause Solution