© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Maintenance

AJ1032

18

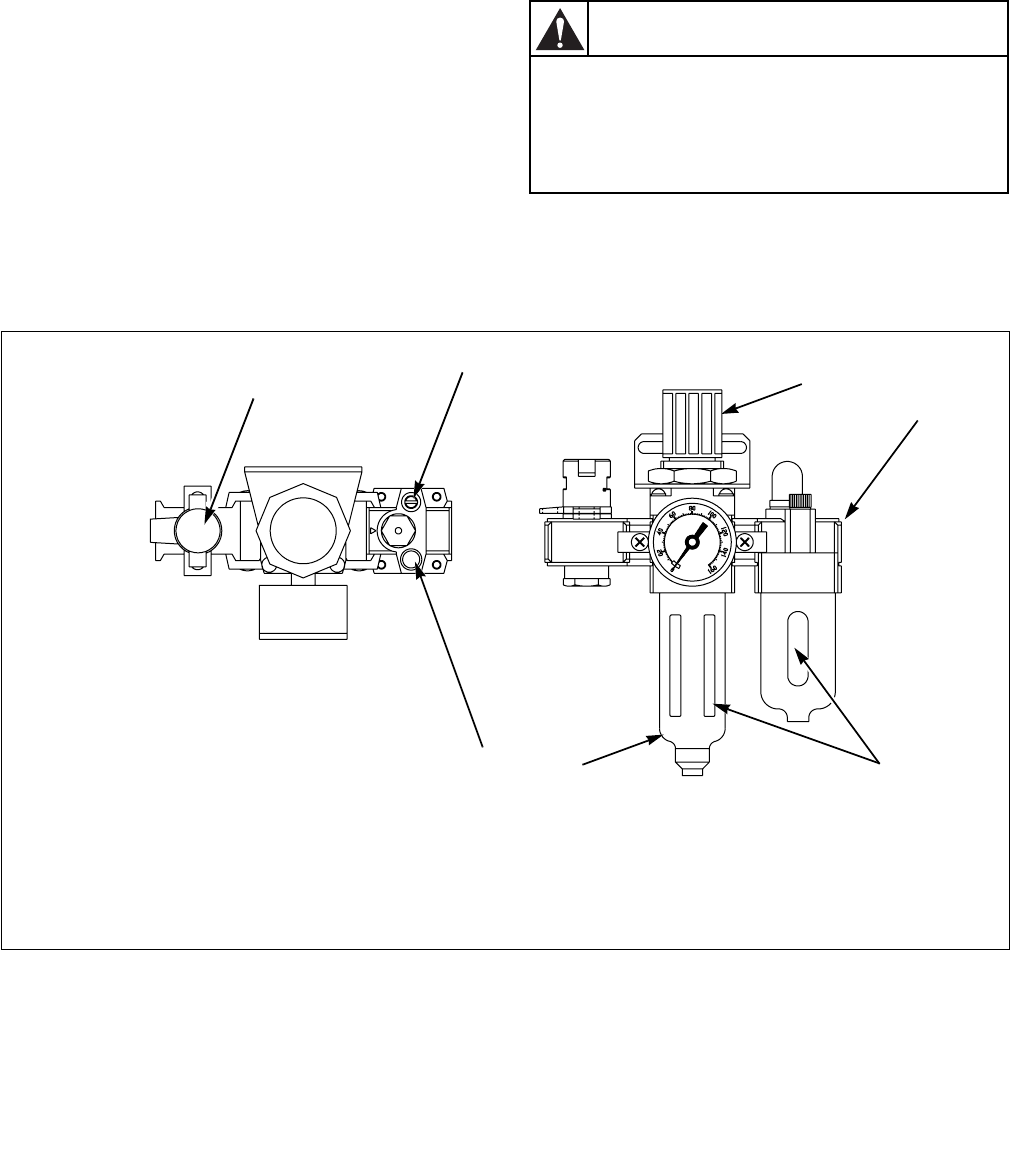

Adjusting Air Line Lubricator Flow Rate

Air system oil lubricator should be adjusted so

approximately one drop of oil every 20 machine cycles

is metered into air system. The following steps outline

the procedure for adjusting air system oil lubricator:

IMPORTANT: To avoid o-ring leaks at top of the

bowl, do NOT remove bowl. Fill through plug.

1. To initially adjust flow rate, turn on air, cycle

press and set screw to obtain desired flow rate.

After system reaches normal operating

temperature, check drip rate again and adjust as

required.

2. To decrease flow rate, turn adjusting screw

clockwise. Likewise, turn counterclockwise to

increase oil flow.

3. Use ISO VG 32 grade oil (refer to Table 3). Refer

to Filling Air Line Lubricator for filling

instructions.

Filling Air Line Lubricator

When oil level falls below 1/4 full, refill bowl to

3/4 full (oil level approximately 1/2 inch [12.7 mm]

from top) with ISO VG 32 grade oil. Refer to Table 3.

NOTE: Do NOT overfill bowl. Damage to filter,

regulator, valves and cylinders WILL result and

void warranty.

Figure 4

To avoid possible serious injury, ALWAYS

close air supply line shut-off valve AND

lock out air service BEFORE filling oil

bowl.

W348

WARNING

SCR103N

1 Oil Flow Rate Adjusting Screw 5 Air Filter

2 Regulator 6 Oil Fill Hole

3 Air Line Lubricator 7 Downstream Relieving Shut-Off Valve

4 Sight Glass

1631605B

6

3

7

1

5

4

2