© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Maintenance

AJ1032

14

Cleaning Press Head

Cleaning press head is periodically required. Press

head requires cleaning if discoloration transfers from

head to garments or garments stick to head as it opens.

Once precautions in above WARNINGS have been

met, follow directions provided with surface cleaner.

Time Intervals Operation or Inspection Corrective Action

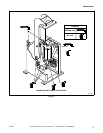

Daily or as required Visually inspect sight glass in air line filter at

inlet. (Refer to Item 4, Figure 4.)

If moisture and oil are collecting in bowl, auto-

drain is not working. Clean, repair or replace

auto-drain.

Check buck padding. Clean padding. Replace padding if it is torn or

brittle or has burn spots.

Visually inspect press head for discoloration or

stickiness.

Clean press head with a head surface cleaner as

needed.

Weekly Inspect air line filter for sediment. Clean air filter if dirt is present.

Inspect all safety labels. Refer to Parts Manual

for location and description of labels.

Replace labels which are damaged, missing or

unreadable.

Every two weeks Inspect steam strainers in steam inlet and outlet

lines and in traps.

Clean steam strainer if dirt is present.

Monthly Inspect customer-furnished steam traps per

instructions provided with traps.

Clean customer-furnished steam traps if dirt is

present.

Check all steam and air connections for visual

signs of leakage.

Tighten any loose connections. Replace lines

where necessary.

Check condition of the flexible steam hoses. Replace steam hoses with broken braids.

Every six months Remove all covers and check cap screws,

fittings and cylinders for security of

attachment.

Tighten as required.

Table 2

To avoid possible serious injury, heads

should be cleaned ONLY by properly

trained personnel.

W342

WARNING

To avoid possible serious injury, ALWAYS

shut off services to press BEFORE

cleaning press heads:

• Shut off AND lock out ALL electric power

to press.

• Shut off AND lock out ALL air pressure to

press using relieving shut-off valve at air

supply inlet.

• Reduce to zero AND lock out ALL steam

pressure to press.

• Let heated surfaces cool.

W343

WARNING

If using a surface cleaner which requires

heat to the press, use industry approved

heat protective mitt or other heat protective

device as press heads are cooling down.

W344

WARNING