© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Maintenance

AJ1032

16

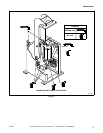

Lubrication

Lubrication points are illustrated in Figure 3.

Lubrication points, time intervals, types and services

are listed in Table 3.

If complete details for lubrication services are not

listed in Table 3, get detailed instructions from

referenced paragraph.

To avoid possible serious injury, ALWAYS

close air supply line shut-off valve AND

lock out air service BEFORE performing

lubrication services.

W347

WARNING

Lubrication Point Time Interval Type of Lubricant Lubrication Service

NOTE: FAILURE to use correct lubricants can result in DAMAGE to machine mechanical components as well as air

system cylinders and valves.

(A) Pressure arm shaft

bearing and cylinder head

bearing

Every three months Use a premium high

temperature EP2 grease.

Lubricate with one shot of

grease from a low pressure

grease gun. If rod end fittings

do not have grease fittings,

squirt a few drops of oil on

rod ends.

(B) Pivot pins, rod ends and

cylinder shaft

Every three months ISO VG 32 grade oil. Squirt a few drops of oil

around circumference of each

shaft.

(C) Air line lubricator As required ISO VG 32 grade oil. Fill bowl to 3/4 full when

level drops below 1/4 full.

Refer to Adjusting Air Line

Lubricator Flow Rate.

(D) Air cylinder Every month ISO VG 32 grade oil. Remove air line at bottom of

cylinder. Prime oil can and

give one complete squeeze

into air line.

NOTE: Buna-N seals are used extensively throughout the valves and cylinders in the air circuit downstream

from the inline oiler. Oils containing graphite fillers, detergent, etc., and fire resistant and synthetic oils are

NOT COMPATIBLE with Buna-N seals. Seal swelling and valve malfunctioning will result with use of

IMPROPER OILS.

Table 3