53

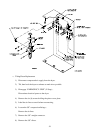

1. Tilting Solenoid Valve

The dryer uses a 3-position/4-way/5-port, spring centering double solenoid valve. With no power applied to

either solenoid, the valve is in a spring centered blocked post state. In this mode, the dryer’s tilting pistons

will remain in their present state, not being able to exhaust air or receive air. When the left solenoid is

energized with 24 VAC, the pilot air pushes the shuttle to the right enabling air to flow into the #2 port and

exhausts #4 port. On 2-Way Tilt models, this is dependent on a supply of external pilot air from the #4 port

of the opposite solenoid valve. When the right solenoid of the valve is energized, air flows through the #4

port and the #2 port exhausts the pilot air, the right side of the valve is always internal pilot.

The tilting solenoid valve has two (2) mufflers. The air is exhausted through these mufflers thereby quieting

the airflow.

2.

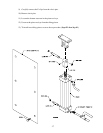

Tilting Pistons

The tilting piston is a double acting cylinder that has a 5-inch (12.7 cm) bore and a 14-inch (35.56 cm) stroke.

When air is applied to the bottom port of the cylinder, the piston begins to extend and air is exhausted through

the top port. Then, if air is applied to the top port, the bottom port will exhaust the air which will cause the

piston to retract.

3.

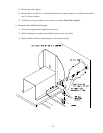

Tilting System Component Replacement

CAUTION: NEVER SERVICE PNEUMATIC COMPONENTS WITH COMPRESSED AIR

CONNECTED. SERIOUS INJURY MAY RESULT.