13

D. ELECTRICAL REQUIREMENTS

It is your responsibility to have ALL electrical connections made by a properly licensed and competent electrician

to assure that the electrical installation is adequate and conforms to local and state regulations or codes. In the

absence of such codes, ALL electrical connections, materials, and workmanship must conform to the applicable

requirements of the National Electrical Code ANSI/NFPA NO. 70-LATEST EDITION or in Canada, the Canadian

Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

IMPORTANT: Failure to comply with these codes or ordinances, and/or the requirements

stipulated in this manual can result in personal injury or component failure.

NOTE: Component failure due to improper installation will VOID THE WARRANTY.

It is required that a separate circuit servicing each basket (tumbler) be provided. The dryer must be connected

with copper wire only. DO NOT use aluminum wire, which could cause a fire hazard.

NOTE: The use of aluminum wire will VOID THE WARRANTY.

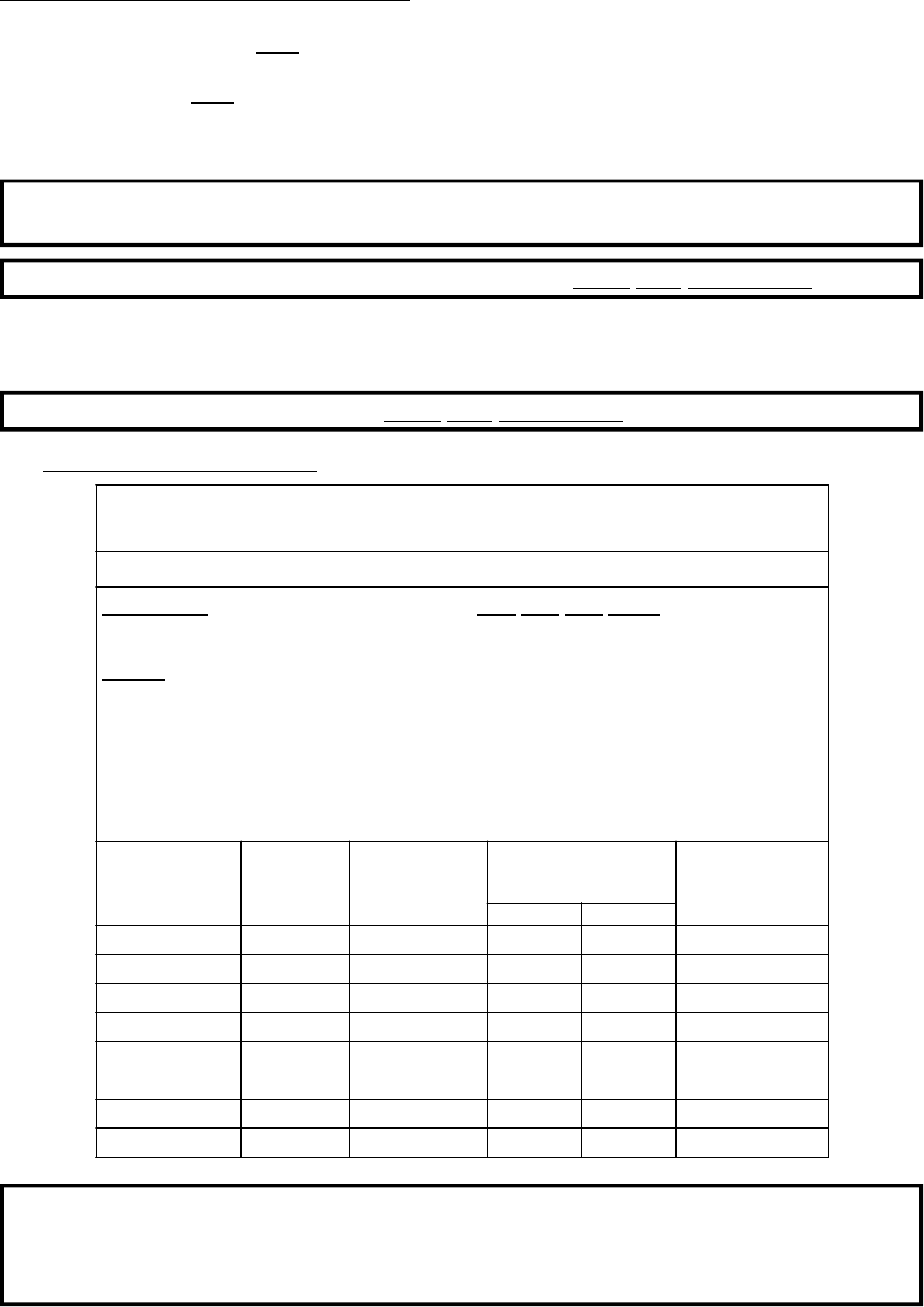

1. Electrical Service Specifications

IMPORTANT: THE DRYER MUST BE CONNECTED TO THE ELECTRIC SUPPLY

SHOWN ON THE DATA LABEL THAT IS AFFIXED TO THE LEFT

SIDE OF THE MAIN ELECTRICAL CABINET LOCATED IN THE

RIGHT HAND ELECTRICAL ENCLOSURE.

GAS

ELECTRICAL SERVICE SPECIFICATIONS (PER DRYER)

IMPORTANT:

NOTES: A.

B.

C.

208 VAC AND 230/240 VAC ARE NOT THE SAME. When ordering,

specify exact voltage.

When fuses are used they must be dual element, time delay, current

limiting, class RK1 or RK5 ONLY. Calculate/determine correct fuse

value, by applying either local and/or National Electrical Codes to

listed appliance amp draw data.

Circuit breakers are thermal-magnetic (industrial) motor curve type

ONLY. For others, calculate/verify correct breaker size according to

appliance amp draw rating and type of breaker used.

Circuit breakers for 3-phase (3ø) dryers must be 3-pole type.

SERVICE

VOLTAGE

PHASE

WIRE

SERVICE

APPROX.

AMP DRAW

CIRCUIT

BREAKER

60 Hz 50 Hz

208 3ø 3 / 4 118.1 — 150

230 3ø 3 108.7 — 150

230 3ø 3 — — —

380 3ø 3 / 4 — 66.8 90

400 3ø 3 / 4 — 67.4 90

416 3ø 3 / 4 — 65.4 90

460 3ø 3 58.9 — 90

480 3ø 3 59.3 — 90