4

!

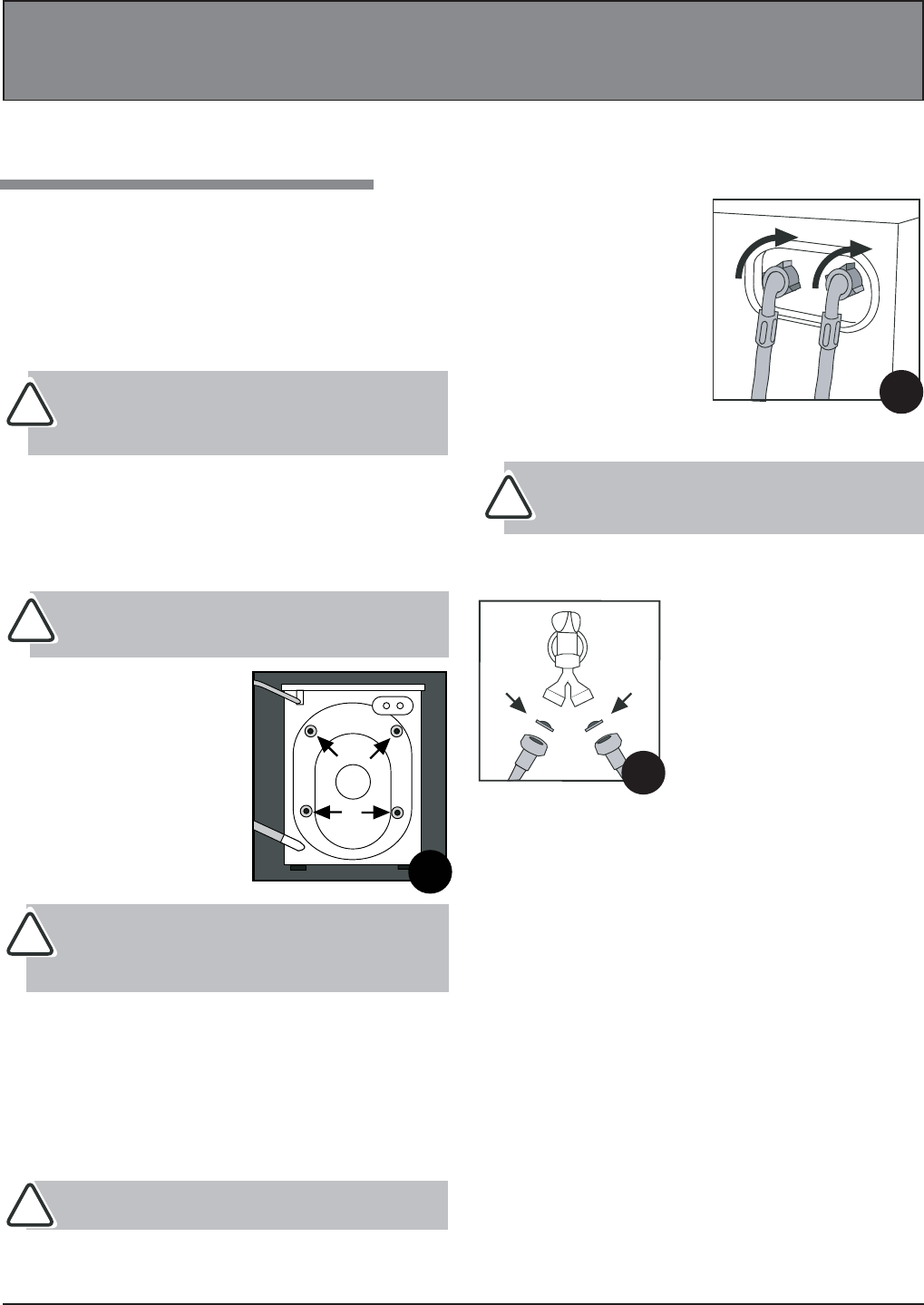

n3. Connecting Water Inlet

• If the water pipes you will be connecting to are new or unused, run the

water until clear to remove any debris that could clog the water valve

screens or valves before connecting the machine. NOTE: Supply

shut-off valves should be easily accessible.

• Included in the accessories supplied with your machine are 2 inlet hoses

with 4 rubber washers preinstalled. Check that the rubber washers are

installed in the ends of the inlet

hoses to make a water tight seal

at each connection point.

• Connect the straight ends of the

water inlet hoses to the supply

taps that have ¾” BSP thread

(standard hose bib).

• Connect the 90º angled ends (20

mm thread) of these hoses to the

inlet valves on the back of the

machine (Fig. 2). NOTE: Water

Inlet valves are color coded:

Red (Hot) & White (Cold).

IMPORTANT: Do not use excessive force. Damage to the

couplings can result. The couplings should be tightened by

hand; a tool should only be used if a leak occurs.

Optional Single Faucet Hook-Up

It is possible to run the machine on

cold water only, but a water supply

must be connected to each inlet

valve. To do this, we suggest you use

a“Y” connector (contact Splendide).

Connect the “Y” connector to a tap.

After checking that the 4 rubber

washers (provided) are installed in the

ends of the inlet hoses, connect the

straight ends of the hoses to the “Y”

connector (Fig. 3). Then connect the

90º angled ends of these hoses to the inlet valves on the back of the

machine (Fig. 2). NOTE: When the machine is connected to a single

faucet, the water temp. for the wash/rinse settings is regulated by the

temperature YOU set at the faucet. If hot or warm water is used for

washing, it is important to turn the faucet to COLD after the wash cycle.

Cold water is essential to your machines

’

condensation drying process.

n1. Unpacking Your Washer-Dryer

• Carefully remove the packing materials with care not to damage the drain

hose and power cord that are shipped installed on the machine. Check

that the machine is intact. Report any damage immediately.

• Position the washer-dryer near the desired installation position.

WARNING: Plastic bags, Styrofoam, nails and other packaging

parts are not children’s toys and can be potentially dangerous.

Destroy the carton and plastic bags after the washer-dryer has

been unpacked.

!

n2. Remove the Transit Screws/Spacers

• For transportation, the inside of the machine is supported by screws,

rubber grommets and spacers on the back panel. Before using the

washer-dryer, these items MUST be removed.

IMPORTANT: Transit screws and spacers must be removed

before operating the machine to allow proper operation of the

machine and to prevent damage to the appliance.

• After positioning the washer-dryer

near the installation location,

remove the four screws (Fig.1), with

the rubber grommets and plastic

spacers that are attached to them.

• Use the plastic plugs (provided in

the accessories bag) to fill in the

holes.

IMPORTANT: Retain the transit screws, spacers and rubber

tubes. These items should be reinstalled to prevent damage if

or when you transport the machine in the future.

!

Installation Instructions

WARNING: Splendide denies all liability if these instructions are not followed correctly.

!

!

Fig. 2

Fig. 3

Continued on next page

n4. Water Drainage

• It is possible for the water to be discharged into a sink, standpipe or

drainpipe, but an air break must be available at a min. 20" height to

prevent the machine from siphoning (Fig. 6).

Standpipe Drain System - Installations require a minimum 1 ¼” (3.2 cm)

diameter standpipe with a minimum carry away capacity of 7 gallons (26

liters) per minute.

Wall or Floor Standpipe Drain System - The top of the standpipe

must be between 25" (62 cm) - 34" (86 cm) from the bottom of the

washer (Fig. 4).

Fig. 1

Installation / Removal

IMPORTANT: Water pressure MUST range within the values

indicated on the “Technical Data” chart (p. 1).