35

M412616

ELECTRICAL REQUIREMENTS

For 30 Pound (13 kg) Narrow Cabinet Tumblers

REQUIREMENTS

Heat Source Electrical Specs Wires Required and Terminal Block Connection

Gas 230-50-1 L1 L2 Ground to PE Busbar

Electric 230-50-1 L1 L2 Ground to PE Busbar

Electric 230-50-3 L1 L2 L3 Ground to PE Busbar

Electric 380-50-3 L1 L2 L3 Ground to PE Busbar

Electric 415-50-3 L1 L2 L3 Ground to PE Busbar

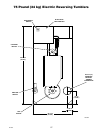

Figure 4

GAS DRYING TUMBLERS

Figure 5

GAS DRYING TUMBLERS

240V, 1 Phase, 50 Hz. 120V, 1 Phase, 30 Hz.

Minimum Wire Size 14 AWG (2.081 mm²) 14 AWG (2.081 mm²)

Circuit Breaker 15 AMP 15 AMP

No. of Poles 2 2

ELECTRIC DRYING TUMBLERS

Figure 6

ELECTRIC DRYING TUMBLERS

240V 50 Hz. 1 Ph 240V 50 Hz. 3 Ph 380V 50 Hz. 3 Ph 415V 50 Hz. 3 Ph

Amp Rating 91 Amp 55 Amp 34 Amp 31 Amp

Circuit Breaker 100 Amp 60 Amp 40 Amp 35 Amp

Poles 2 3 3 3

Minimum Wire Size 2 AWG (33.63 mm²) 6 AWG (13.32 mm²) 8 AWG (8.366 mm²) 8 AWG (8.366 mm²)

GROUNDING INSTRUCTIONS

Drying tumbler must be grounded. In event of malfunction or breakdown, grounding will reduce risk of electric

shock by providing a path of least resistance for electric current. Drying tumbler must be connected to a

grounded metal, permanent wiring system; or an equipment grounding conductor must be run with circuit

conductors and connected to PE Busbar.

ࡽ

WARNING

To reduce the risk of fire and electric shock, check with a qualified serviceman for

proper grounding procedures. Improper connection of the equipment grounding

conductor can result in a risk of electric shock.

WARNING

ࡽ

To reduce the risk of fire and electric shock, if electrical supply is coming from a

three phase service, DO NOT connect a “Stinger Leg” to a single phase machine.