36

nstallation

I

Water supply pressure must be between

30kPa and 1000kPa (0.3~10kgf/cm

2

)

Don’t strip or crossthread when connecting

Inlet hose to the valve.

If the water supply pressure is more than

1000kPa, a decompression device should be

installed.

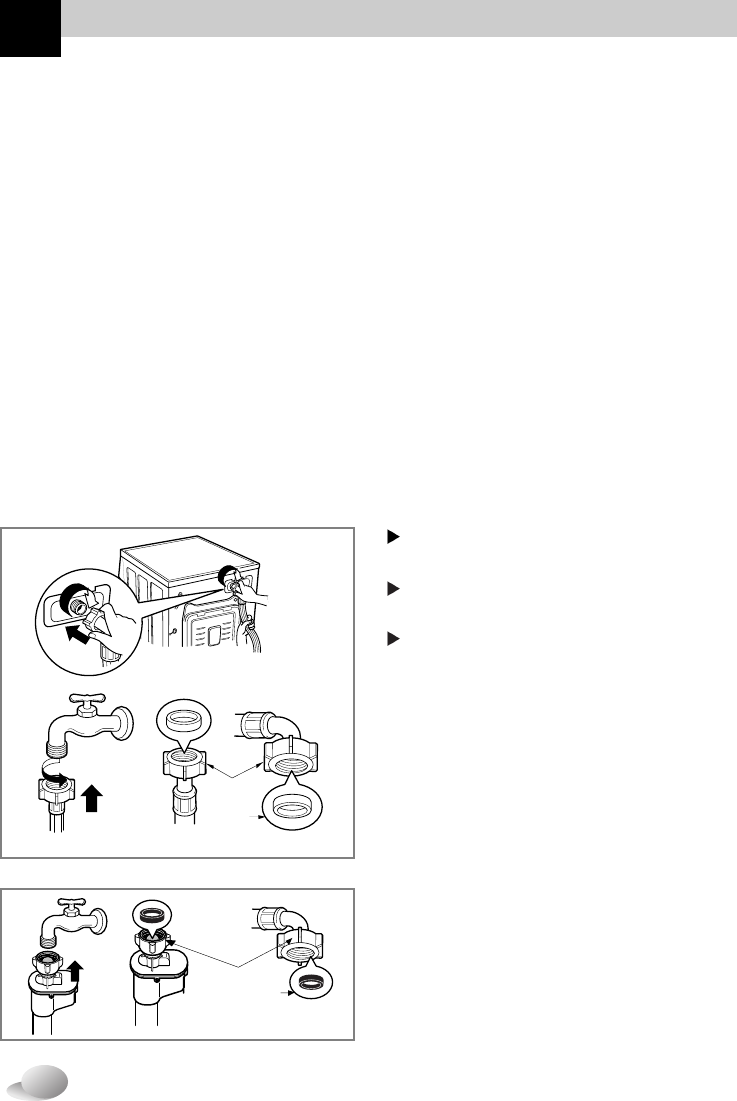

• Two rubber seals are supplied with the

water inlet hoses these are in order to

prevent water leaks.

• Check water tightness of washing

machine connections by turning the tap

completely on.

• Periodically check the condition of the

hose and replace the hose if necessary.

• Make sure that there is no kink on the

hose and that it is not crushed.

Washing Machine is to be connected to the water mains using new hose-

sets and that old hose-sets should not be used.

Connecting water supply hose

Rubber seal

Hose connector

Rubber seal

Hose connector

1. Do not use an extension cord or double adapter.

2. If the supply cord is damaged, it must be replaced by the manufacturer or its service agents

or similarly qualified person in order to avoid a hazard.

3. Always unplug the machine and turn off the water supply after use.

4. Connect the machine to an earthed socket in accordance with current wiring regulations.

5. The appliance must be positioned so that the plug is easily accessible.

• Repairs to the washing machine must only be carried out qualified personnel. Repairs carried out by

inexperienced persons may cause injury or serious malfunctioning. Contact your local service center

• Do not install your washing machine in rooms where temperatures below freezing may occur. Frozen

hoses may burst under pressure. The reliability of the electronic control unit may be impaired at

temperatures below freezing point.

• If the appliance is delivered in the winter months and temperatures are below freezing : Store the

washing machine at room temperature for a few hours before putting it into operation.

Electrical connection