40 AC-Series Operator’s Manual-E/F

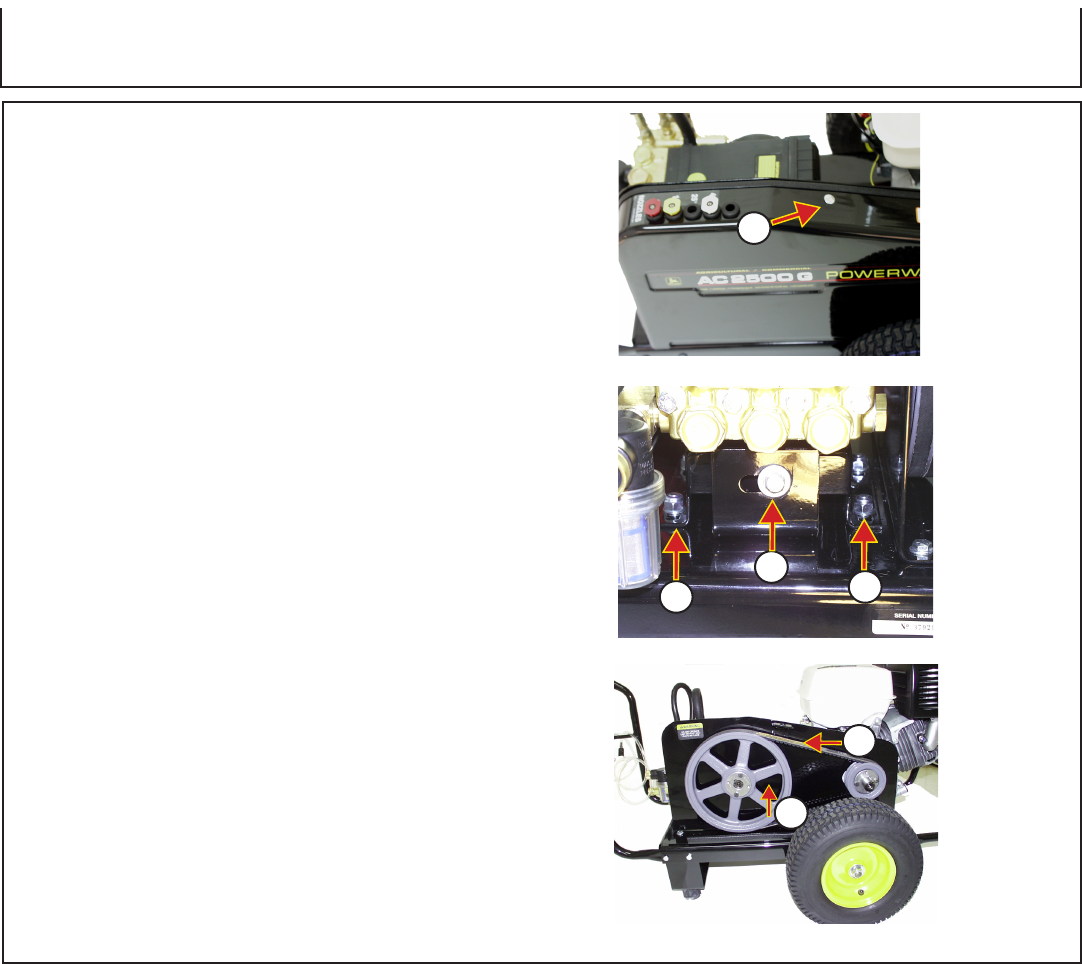

ADJUST BELT TENSION -

AC-2500GH & AC-3500GH ONLY

NOTE: Check/adjust belt tension after every 25 hours of

use.

1. Twist locking screw (A) 1/4 turn and lift off belt guard.

2. Inspect belts for wear, cracks or fraying. Replace belts

if damaged.

3. Loosen the four bolts (A) holding pump mounting

bracket to chassis.

4. Tighten adjusting cap screw (B) to take slack out of

belt.

5. In the four-bolt pattern that holds the pump mounting

bracket to chassis, rst tighten mounting bracket corner

bolt which is closest to both the motor and the belts.

(Right rear bolt in illustration.)

6. Continue tightening adjusting cap screw (B) until

pulleys are aligned parallel to straightedge (C), and

13mm (1/2 inch) deection occurs at belt midpoint (D)

when belt is depressed with nger.

NOTE: Process may have to be repeated several times to

maintain pulley alignment while producing 13mm

(1/2 inch) belt deection.

7. Tighten all four pump mounting bracket bolts (A).

8. Install guard.

PIC105-102299R0

PIC104-101599R0

PIC106-102299R0

A

Service

B

A

A

D

C