© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

55

9001000

Control Function Test

The washer-extractor should be cleaned after the

installation is complete. A function test should then be

executed on the unloaded machine:

1. Verify that power supply voltage and phase are

correct in accordance with the washer-extractor’s

requirements.

2. Open manual shut-off valves to the washer-

extractor.

3. Press the Emergency Stop button.

4. Apply power to the washer-extractor.

5. Release the Emergency Stop button.

6. Check the door interlock before starting

operation:

a. Attempt to start the washer with the door

open. The washer-extractor should not start

with the door open.

b. Close the door without locking it and attempt

to start the washer. The washer should not

start with the door unlocked.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

7. For standard processing, select Cycle 01 by

pressing key 0 and key 1 on the keypad. Then

press the Start key (or run factory test cycle 39 by

pressing key 3, key 9 and Start key).

Run a complete cycle, checking operation of

water inlet valves, drain, and extract functions.

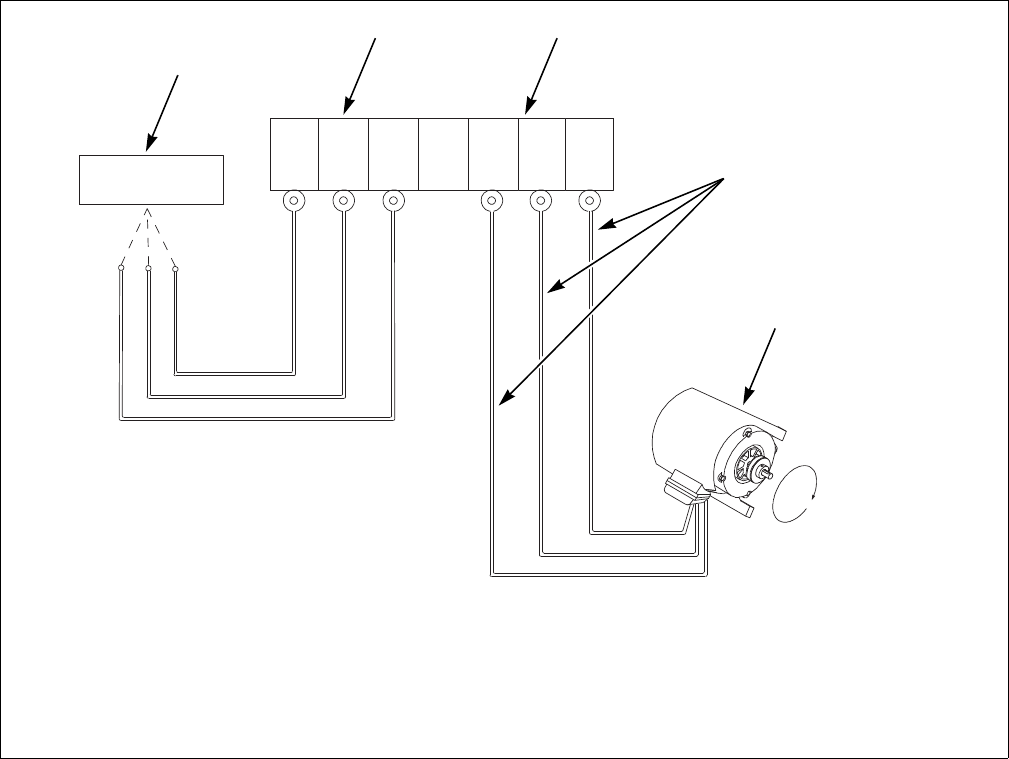

8. Cylinder rotation must be clockwise in an extract

step for all models. If rotation is not correct,

disconnect power. A qualified electrician must

reverse any two leads between the AC drive and

the main drive motor. Refer to Figure 42.

Figure 42

CFD10N

1 Power Supply 4 Motor Leads (Swap any 2 of the 3 motor leads

to change rotation direction)

2 Typical Connection (See machine schematic or

invertor drive for details of electronic

connections)

5 Main Drive Motor

3 AC Drive Connections

CFD10N

MACHINE

(L1) (L2) (L3)

1

3

5

4

2