Electrical

connection

: ::: : ah

-::

.:

:.:

:

:: ::; ,:

*

Electrical Shock Hazard

: 2 : Turn power supply off before

: !

il.-$ connecting cord.

.:.: :. :

-i:ij.$ Use a new 30 ampere power

.i’l’i ; supp,y cordm

‘:.!. Plug into a grounded outlet.

j i ! Failure to follow these

; ; .: instructions can result in

:

: :

: :

death, fire, or electrical shock.

1

. Turn power supply off.

2

. Remove hold-down screw and

terminal block cover.

external

ground

connecto- $o$

I terminal I /

tab

block cover

x

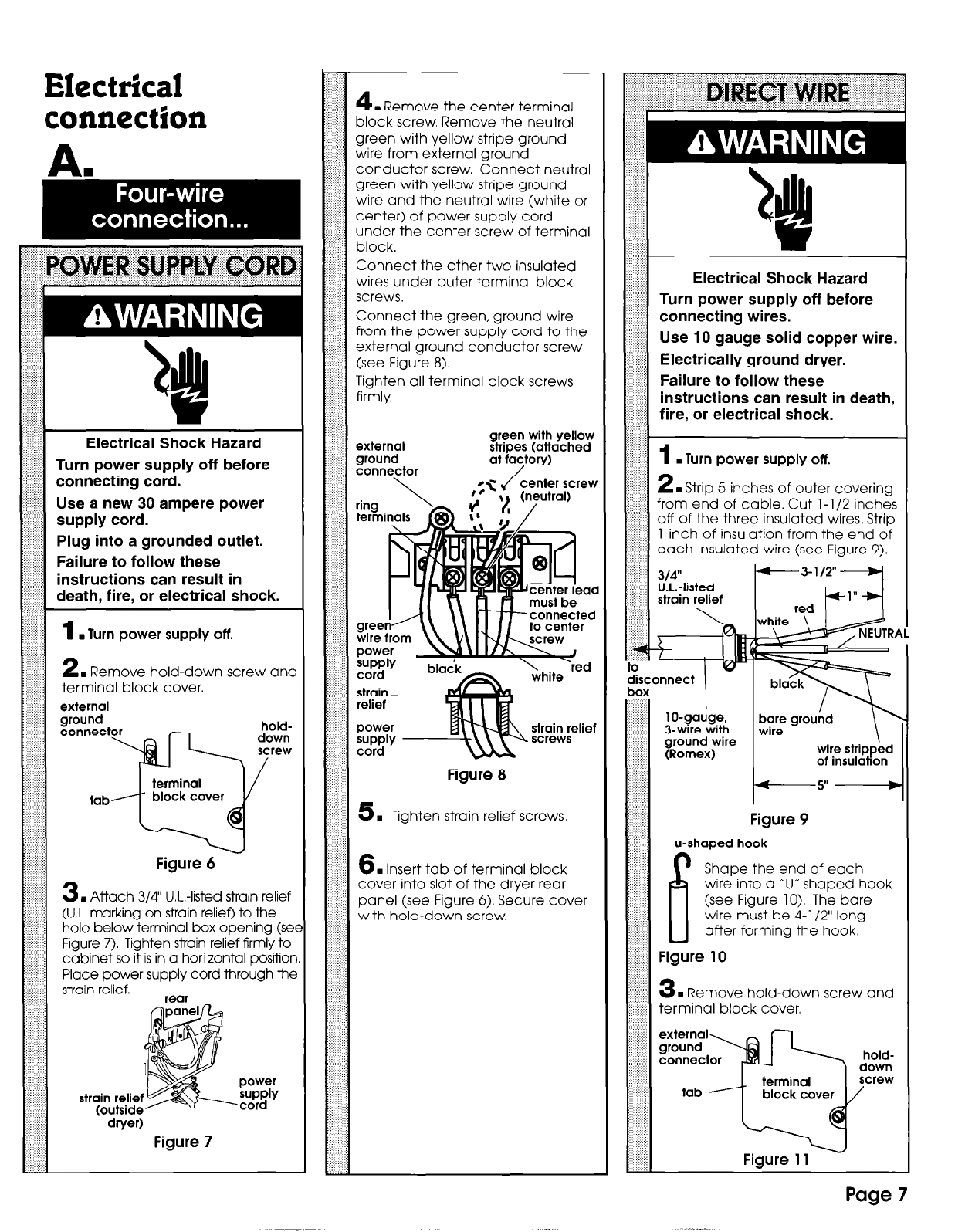

Figure 6

3

. Attach 3/4” U.L.-listed strain relief

(U.L. marking on strain relief) to the

hole below terminal box opening (set

Figure 7). Tighten strain relief firmly to

cabinet so it is in a horizontal position

Place power supply cord through the

strain relief.

rear

strain relief

(outside

power

~o~$lY

dryer)

Figure 7

3

I,

4

. Remove the center terminal

block screw. Remove the neutral

green with yellow stripe ground

wire from external ground

conductor screw. Connect neutral

green with yellow stripe ground

wire and the neutral wire (white or

center) of power supply cord

under the center screw of terminal

block.

Connect the other two insulated

wires under outer terminal block

screws.

Connect the green, ground wire

from the power supply cord to the

external ground conductor screw

(see Figure 8).

Tighten all terminal block screws

firmly.

external

ground

connector

green with yellow

stripes (attached

at factory)

/

termi

‘/

green

wire from

Figure 8

5

. Tighten strain relief screws

6

. Insert tab of terminal block

cover into slot of the dryer rear

panel (see Figure 6). Secure cover

with hold-down screw.

.:

,.: :.

:: .:: ::

ah

:

:

: 1

*

Electrical Shock Hazard

Turn power supply off before

connecting wires.

Use 10 gauge solid copper wire.

Electrically ground dryer.

Failure to follow these

instructions can result in death,

fire, or electrical shock.

. Turn

power supply off.

ion from the end of

each insulated wire (see Figure 9).

tis;onnect

I

I

1 O-gauge,

J-wire with

ground wire

(Romex)

t

red

wire stripped

ot insulation

-5”-

Figure 9

u-shaped hook

P

Shape the end of each

wire into a ‘U” shaped hook

(see Figure 10). The bare

wire must be 4-l/2” long

after forming the hook.

Figure 10

3

. Remove hold-down screw and

terminal block cover.

hold-

down

screw

/

Figure 11

Page 7