Exhaust

requirements

/

f

Aa

I

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to do so can result in

death or fire.

Do not use non-metal flexible vent,

metal vent that is smaller than four

inches in diameter or exhaust hoods

with magnetic latches.

Do not exhaust dryer into a chimney,

furnace cold air vent, al-tic of crawl

space, or any other vent used for

venting.

Do not install flexible vent in enclosed

walls, ceilings or floors.

If using an existing exhaust system, clear

lint from entire length of exhaust system

Make sure exhaust hood is not plugged

with lint.

The exhaust system should be inspectec

and cleaned yearly.

Replace any vinyl or metallized plastic

foil exhaust vent with rigid metal or

flexible metal vent.

Use

duct tape

to

seal all joints.

exhaust airflow

Four-inch

metal exhaust vent is reql

Plan installation to use the fewest

number of elbows and turns.

lired.

Metal flexible vent

must be fully

extended and supported when the

dryer is in its final position. DO NOT

KINK OR CRUSH THE VENT. The metal

flexible vent must be completely

open to allow adequate exhaust air

to flow.

Allow as much room as possible

when using elbows or making turns.

Bend vent gradually to avoid kinking.

Remove excess flexible vent to avoid

sagging and kinking that may result in

reduced air flow.

Exhaust outlet is located at the

center of the bottom dryer back.

The exhaust vent can be routed up,

down, left, right, behind the dryer or

straight out the back of the dryer.

Kits are available to convert the

exhaust vent to be routed through

the cabinet right or left side or

through the bottom. See Page 3 for

Exhaust Kit part numbers. See Page

11 for product dimensions and

recessed area requirements.

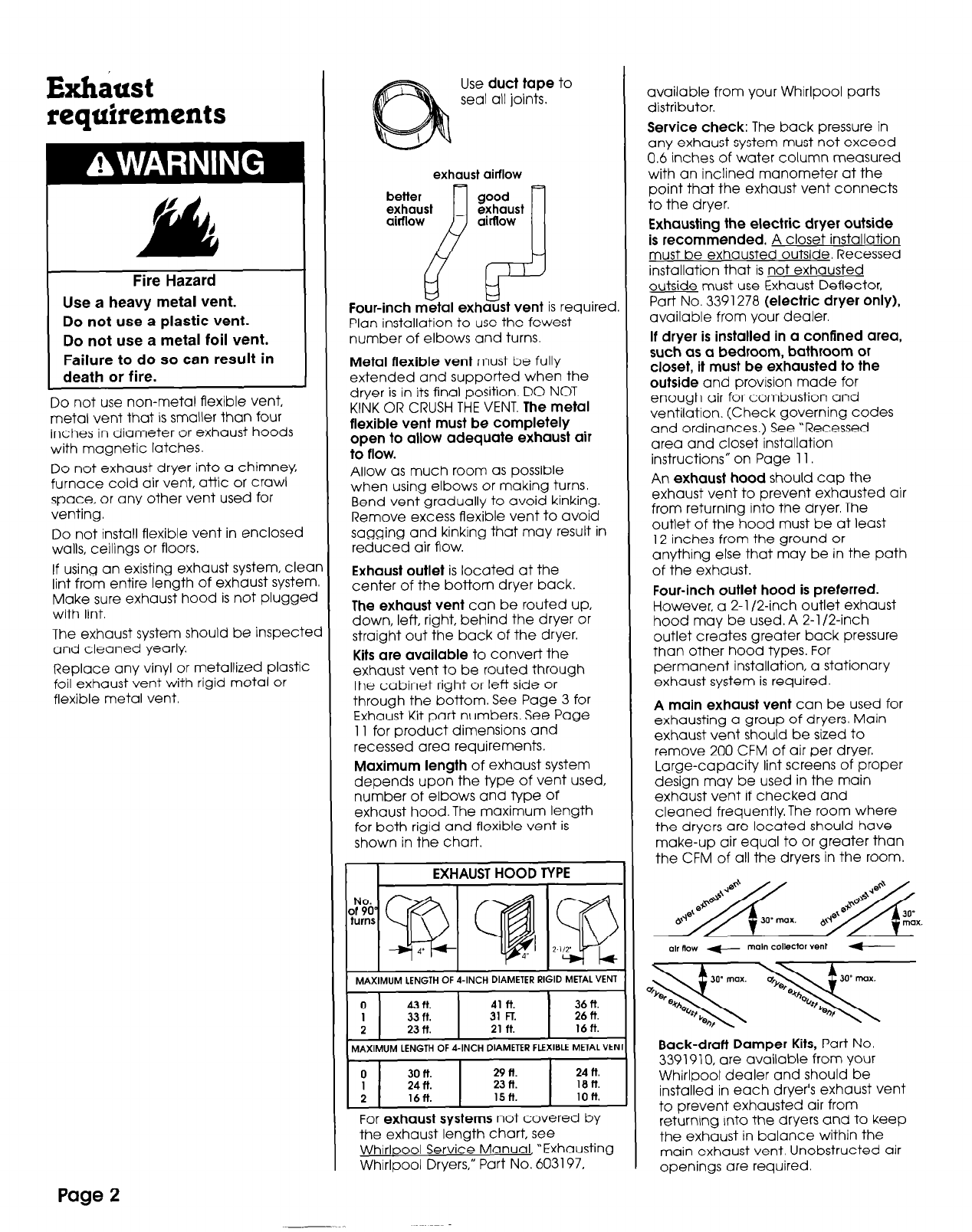

Maximum length of exhaust system

depends upon the type of vent used,

number of elbows and type of

exhaust hood. The maximum length

for both rigid and flexible vent is

shown in the chart.

I

EXHAUST HOOD

TYPE

I I

I

I

I

MAXIMUM LENGTH OF 4-INCH DIAMETER RIGID METAL VENT

0

43 n.

41 ft. 36 f-t.

1 33 ft. 31 Fr. 26 ft.

2

ii it.

21 ft.

16 ft.

MAXIMUM LENGTH OF 4-INCH DIAMETER FLEXIBLE METAL VEN

0

30 ft.

29 ft. 24 ft.

1

24 ft.

23 ft.

18 n.

2

16ft.

15

n.

10 n.

For exhaust systems not covered by

the exhaust length chart, see

Whirloool Service Manual, “Exhausting

Whirlpool Dryers,” Part No. 603197,

available from your Whirlpool parts

distributor.

Service check: The back pressure in

any exhaust system must not exceed

0.6 inches of water column measured

with an inclined manometer at the

point that the exhaust vent connects

to the dryer.

Exhausting the electric dryer outside

is recommended. A closet installation

must be exhausted outside. Recessed

installation that is not exhausted

outside must use Exhaust Deflector,

Part No. 3391278 (electric dryer only),

available from your dealer.

If dryer is installed in a confined area,

such as a bedroom, bathroom or

closet, it must be exhausted to the

outside and provision made for

enough air for combustion and

ventilation. (Check governing codes

and ordinances.) See “Recessed

area and closet installation

instructions” on Page 11.

An exhaust hood should cap the

exhaust vent to prevent exhausted air

from returning into the dryer. The

outlet of the hood must be at least

12 inches from the ground or

anything else that may be in the path

of the exhaust.

Four-inch outlet hood is preferred.

However, a 2-l/2-inch outlet exhaust

hood may be used. A 2-l/2-inch

outlet creates greater back pressure

than other hood types. For

permanent installation, a stationary

exhaust system is required.

A main exhaust vent can be used for

exhausting a group of dryers. Main

exhaust vent should be sized to

remove 200 CFM of air per dryer.

Large-capacity lint screens of proper

design may be used in the main

exhaust vent if checked and

cleaned frequently. The room where

the dryers are located should have

make-up air equal to or greater than

the CFM of all the dryers in the room.

Back-draft Damper Kits, Part No.

3391910, are available from your

Whirlpool dealer and should be

installed in each dryer’s exhaust vent

to prevent exhausted air from

returning into the dryers and to keep

the exhaust in balance within the

main exhaust vent. Unobstructed air

openings are required.

Page 2