ELECTRICAL REQUIREMENTS

[

ELECTR/CDryer

CIRCUIT- Individual 30 amp. branch circuit fused with 30 amp.

time delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers, and DO

NOToperate a washer and a dryer on the same circuit.

POWER SUPPLY - 3 wire, 240 volt, single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD KIT - The dryer MUST employ a 3-

conductor power supply cord NEMA 10-30 type SRDT rated at

240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. If being installed in a new

branch circuit installation, manufactured (mobile) home,

recreational vehicle or area which prohibits grounding through

the neutral conductor, the dryer MUST employ a 4-conductor

power supply cord NEMA 14-30 type SRDTor ST(as required)

rated at 240 volt AC minimum, 30 amp., with 4 open end spade

lug connectors with upturned ends or closed loop connectors

and marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FORA 4-WIRE SYSTEM.

OUTLET RECEPTACLE- NEMA 10-30R or 14-30R receptacle to

be located so the power supply cord is accessible when the dryer

is in the installed position.

Typical 3-wire installation

POWER SUPPLY

3 WIRE GROUNDED NEUTRAL

4 120-240 VOLT 60 CYCLE

MAIN FUSE BOX

30 AMP DELAYED ACTION

FUSES

OR CIRCUIT BREAKER

NEUTRAL WIRE

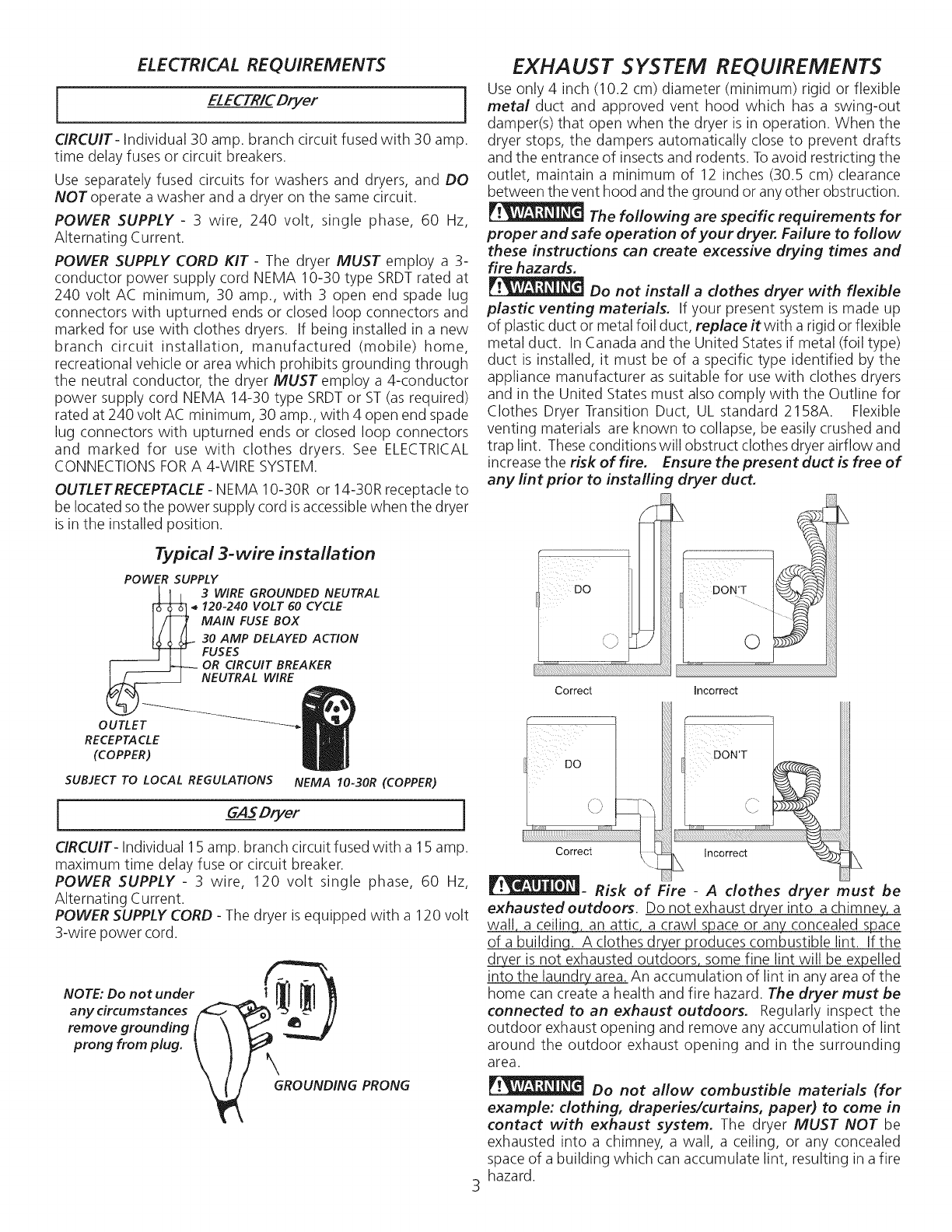

EXHA LIST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a dothes dryer with flexible

plastic venting materials, If your present system is made up

of plastic duct or metal foil duct, replace it with a rigid or flexible

metal duct. In Canada and the United States if metal (foil type)

duct is installed, it must be of a specific type identified by the

appliance manufacturer as suitable for use with clothes dryers

and in the United States must also comply with the Outline for

Clothes Dryer Transition Duct, UL standard 2158A. Flexible

venting materials are known to collapse, be easily crushed and

trap lint. Theseconditions will obstruct clothes dryer airflow and

increase the risk of fire, Ensure the present duct is free of

any lint prior to installing dryer duct.

©

Correct Incorrect

OUTLET

RECEPTACLE

(COPPER)

SUBJECT TO LOCAL REGULATIONS NEMA 10-30R (COPPER)

GAS Dryer

J

CIRCUIT- Individual 15 amp. branch circuit fused with a 15 amp.

maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD - The dryer is equipped with a 120 volt

3-wire power cord.

NOTE: Do not under

remove grounding

prong from plug.

ROUNDINGPRONG

DO

Correct

_- Risk of Fire - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building A clothes dryer produces combustible lint. If the

dryer is not exhausted outdoors some fine lint will be expelled

into the laundry area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors, Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surrounding

area.

Do not allow combustible materials (for

example: clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT be

exhausted into a chimney, a wall, a ceiling, or any concealed

space of a building which can accumulate lint, resulting in a fire

hazard.