17

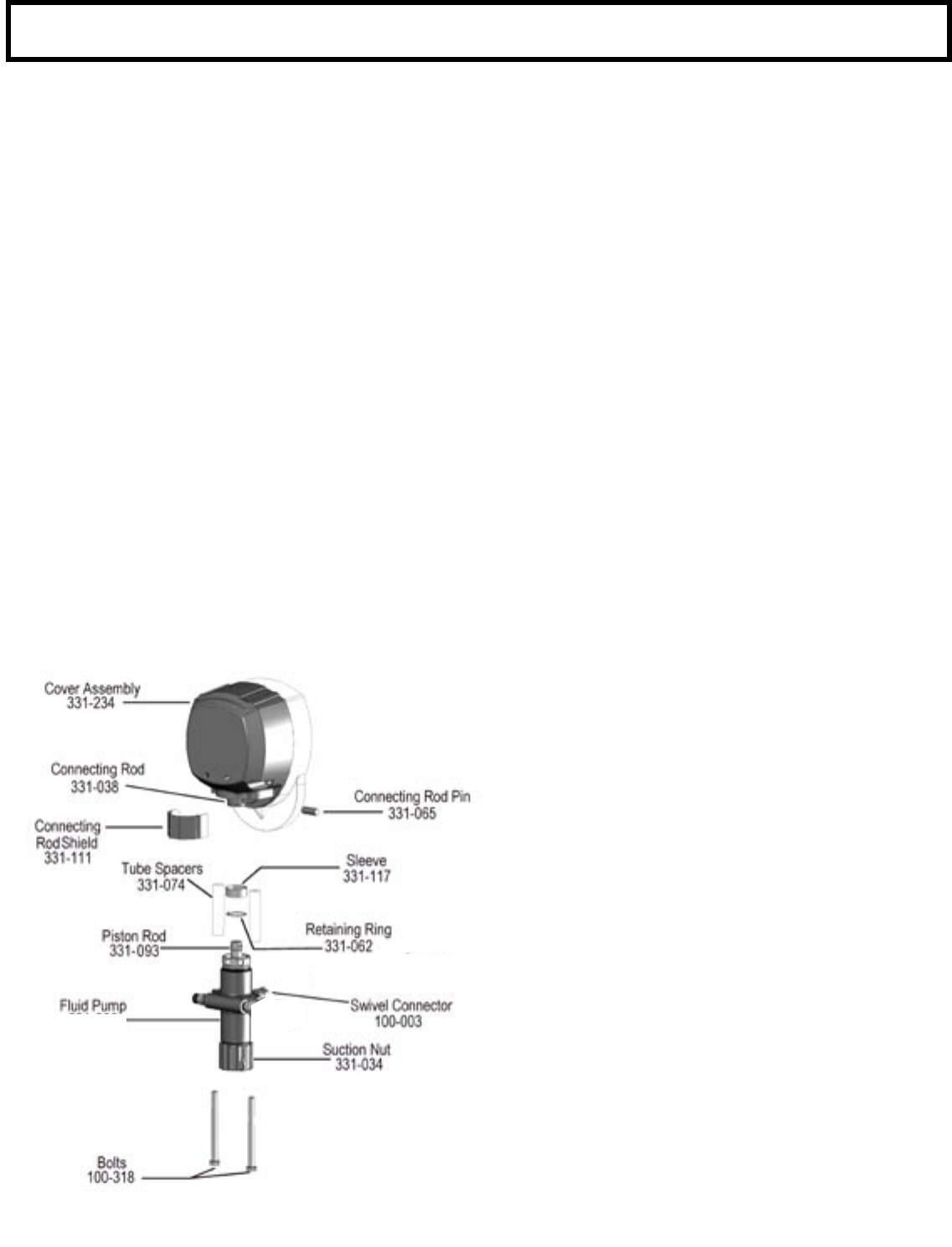

Refer to Figure 1

1. Follow the Pressure Relief Procedure on page 10.

2. Flush the material you are spraying out of the machine.

3. Remove the connecting rod shield (331-111).

4. Move the piston rod (331-093) to its lowest position

by cycling pump slowly.

5. Remove the retaining ring (331-062) from the

connecting rod (331-038) and slide the sleeve (331-

117) down revealing the connecting rod pin (331-065).

6. Remove the suction tube assembly from the uid

pump (331-209) by unscrewing the suction nut

(331-034) with the packing adjustment tool.

7. Using a 1/2” wrench unscrew the two bolts (100-318)

from the cover assembly (331-234). The uid pump

(331-209) will be hanging loosely at this point.

8. Remove the connecting rod pin (331-065) out of

the connecting rod (331-038), allowing the removal

of the uid pump (331-209) from the machine.

FIGURE 1

Servicing the Fluid Pump

Fluid Pump Disconnect

Fluid Pump Reinstall

Refer to Figure 1 & 4

1. Loosen the packing nut and ensure that the piston rod

(331-093) is in its upper position in the uid pump body

(331-011). Slip the sleeve (331-117) & the retaining

ring (331-062) over the piston rod.

2. Push the piston rod up into the connecting rod (331-

038) & align the holes. Insert the connecting rod pin

(331-065) through the connecting rod & piston. Slip

the sleeve up over the connecting rod pin and insert

the retaining ring into the groove on the connecting rod.

3. Push the two bolts (100-318) through the tube spacers

(331-074) & screw them into the cover assembly (331-

234). Using a 1/2” wrench, tighten the two bolts evenly

(alternating between them) until you reach 20 ft-lbs.

4. Reassemble lower suction valve assembly by placing

the suction seat (331-409), O-ring (106-011), suction

ball (331-030) & suction ball guide (331-029) in the

suction nut (331-034) & screw onto uid pump body.

5. Start the machine and operate slowly to check the piston

rod for binding. Adjust the two bolts, holding the uid

pump body to the cover assembly, if necessary. This

will eliminate any binding.

6. Tighten the packing nut clockwise until resistance is

felt against the Belleville Springs, then go 3/4 of a turn

more. Put ve drops of Airlessco Throat Seal Oil into the

packing nut.

7. Run the machine at full pressure for several minutes.

Release the pressure by following the Pressure Relief

Procedure & readjust the packing nut per step 6 above.

8. Install the connecting rod shield (331-111) so that the

small hole is in the upper right hand corner.

331-209