8 9

Using Attachments

NOTE:Wheninstallingorchangingattachments,besuretheunitisoff,unplugged,andno

steamisbeingreleasedtoavoidcontactwithhotwater.

1.Fabric Brush

Helpsopenthefabricforgreatersteampenetration.

-Attachthefabricbrushontothesteamnozzle(Fig.3).

-Movethefabricbrushinadownwardmotionfromtoptobottomgentlybrushingthefabric.

2.Crease Clamp

Helpscreateastraightcrease

-Attachthecreaseclamptothesteamnozzle(Fig.5).

-Pushthetriggertoopenthecreaseclamp.

-Placethegarmentbetweenthecreaseclampandsteamnozzle.

-Releasethetrigger.

-Movethecreaseclampinadownwardmotionfromtoptobottomtosetacrease.

Cleaning and Maintenance

1.Besurethesteameristurnedoffandunplugged.

2.Allowthesteamertocoolforatleast30minutes.

3.Emptyanyexcesswaterfromthewatertankandallowittoairdrybeforereplacingthecap

andsettingitbackintheunit.

4.Emptyexcesswaterfromthereservoirbytippingunitoverasink.

Storing

1.Openthe3clips(Fig.2)onthetelescopicpoleandglideitslowlyto

collapsebeingcarefulnottopinchyourfingers.Whenitisallthewaydown

closethe3clipsbackintoplace.

2.Coilthehoseandplaceonthehangerattachment(Fig.9)

3.Storeinacool,dryplace.

Removing Mineral Buildup

Onecommonproblemwithsteamersismineralbuildupcausedbythehighmineralcontent

inmanymunicipalwatersupplies.Mineralresidueinsideoftheinternalpipesandheatercan

causeintermittentsteamingorinseverecasesnosteamingatall.

Thebestwaytoavoidthisistousede-mineralizedordistilledwaterintheunit.Theprocedure

belowcanbeusedtoclearmineralbuildup.Ifyouareunabletousede-mineralizedordistilled

waterwerecommendyouusethisprocedureevery30hoursofoperationtohelpavoidmineral

buildup.

1.Turntheunitoffandunplugthepowercord.

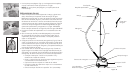

2.Unscrewandremovethehosefromthehoseconnectoronthetopoftheunit.

3.Removethepolefromtheunit.

4.Removethewatertankfromthemainunitanddrainanywaterintheunitoverasink.

5.Makeamixtureof4oz.whitevinegarand4oz.water.Inmostcases1cupofthismixturewill

besufficient.

6.Slowlypourthewater-vinegarmixtureintothehoseconnector(Fig.11).

a.Iftheinternalpipingisonlypartiallyblockedbymineralbuildup,thewater-vinegarmixture

willsoonstartflowingoutofthewaterintakehole.Ifthishappensproceedtostep8.

b.Iftheinternalpipingiscompletelyblocked,continuetopourthemixtureintothehose

connectoruntilfull.

7.Pourthewater-vinegarmixtureintothewaterintakeholeuntilfull.

8.Letstandfor40minutes.

9.Drainthewater-vinegarmixturefromhoseconnectororthereservoirbytippingtheunitovera

sink.

Pourcleanwaterthroughthehoseconnectorandwaterintakeholeuntilthevinegarsmell

dissipates.

Draintheresidualwaterfromhoseconnectororthereservoirbytippingtheunitoverasink.

Reassembletheunitandoperatenormally.

Iftheprocedureabovedoesnotreturntheunittonormaloperation,theunitmayneedservicing.

10.

11.

12.

Hose

Connector

Water Intake

Hole

Figure 11

Figure 9