12 American Dryer Corporation 450431-3

To Replace Gas Valve

(Refer to burner illustration on the next page)

Discontinue electrical power to the dryer.

Close shutoff valve(s) in gas supply line.

Disconnect gas valve wiring.

NOTE: Identify location of each wire for correct

reinstallation.

Break union connection before gas valve.

Loosen and remove screws (4) securing pipe brackets to

burner.

Remove gas valve/manifold assembly from dryer.

Remove valve mounting bracket, manifold, and piping from

gas valve.

Reverse procedure for installing new gas valve.

To Replace Main Burner Orifices

Refer to “To Replace Gas Valve” and follow the steps until

manifold is removed then unscrew main burner orifices and

replace.

NOTE: Use extreme care when removing and replacing

orifices. These orifices are made of brass and are easily

damaged.

Reversing the removal procedure for reinstalling.

▲ WARNING

!

Test all connections for leaks by brushing on a

soapy water solution.

Never test for leaks with a flame!!!

To Test and Adjust Gas (Water Column) Pressure

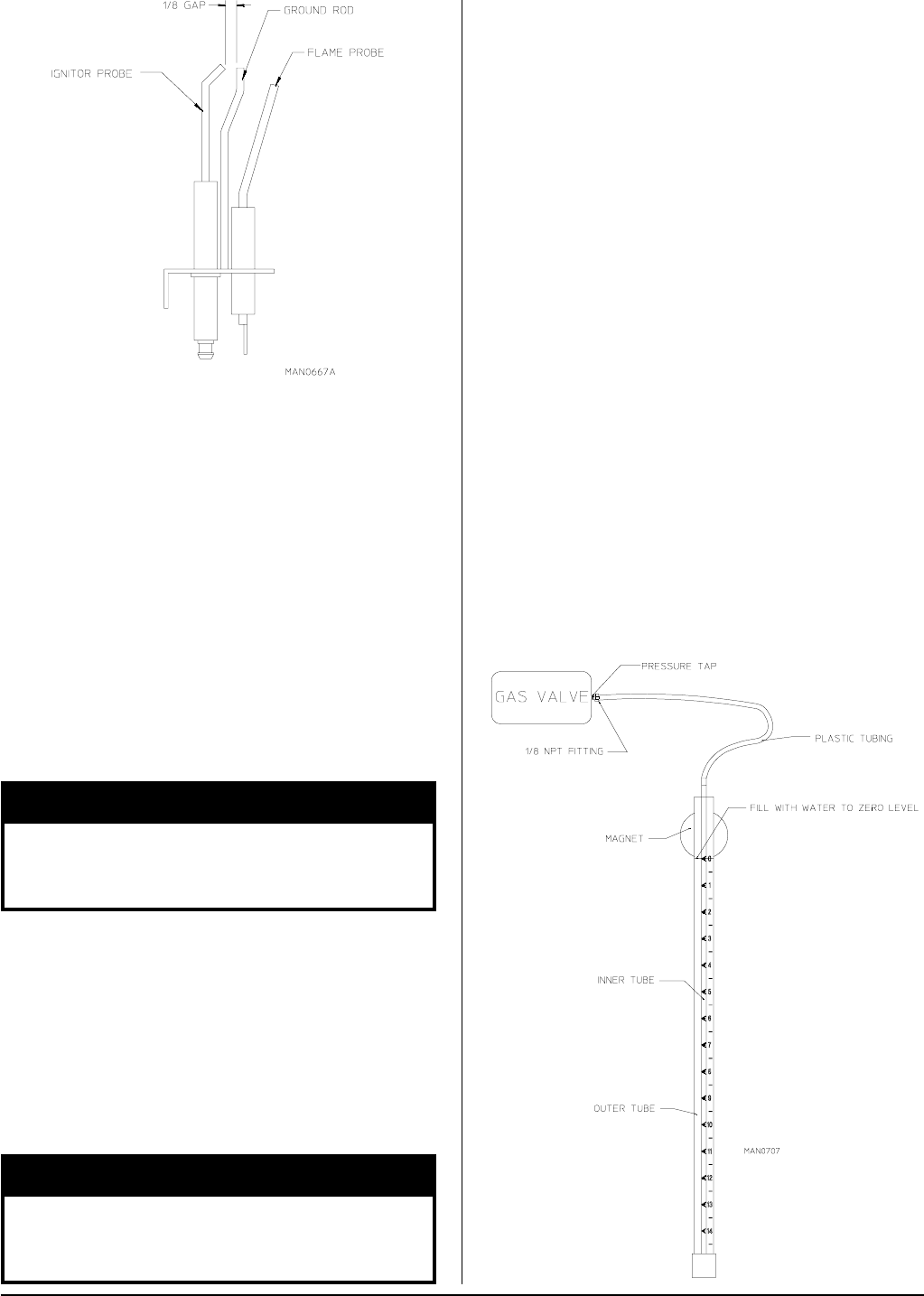

There are two types of devices commonly used to measure

water column pressure. They are spring/mechanical-type

gauges and manometers. The spring/mechanical-type gauge

is not recommended, because it is easily damaged and not

always accurate. A manometer is simply a glass or

transparent plastic tube with a scale in inches. When filled

with water and pressure applied, the water in the tube rises

showing the exact water column pressure.

NOTE: Manometers are available from the factory by

ordering ADC P/N 122804.

To Test Gas Water Column Pressure:

Connect water column test gauge connection to gas valve

pressure tap (1/8” N.P.T.). This pressure tap is located on

the outlet (manifold) side of the valve.

Start dryer. With burner on, the correct water column reading

in inches would be:

Natural Gas – 3.5 in wc; L.P. Gas – 10.5 in wc

To Adjust Water Column Pressure (natural gas only, L.P. gas

must be regulated at source):

Remove the slotted vent cap on the top of the valve.

Turn the slotted adjustment screw, located on the top of the

valve next to the terminals clockwise to increase manifold

pressure and counterclockwise to decrease.

NOTE: If correct water column pressure cannot be

achieved, problem may be due to an undersized gas

supply line, a faulty or underrated gas meter, etc.

▲ WARNING

!

Test all connections for leaks by brushing on a

soapy water solution.

Never test for leaks with a flame!!!