6

Gas supply line

Must include " NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the washer/dryer (see illustration).

" IPS pipe is recommended.

" approved aluminum or copper tubing is acceptable for

lengths under 20 ft (6.1 m) if local codes and gas supplier

permit.

If you are using Natural gas, do not use copper tubing.

Lengths over 20 ft (6.1 m) should use larger tubing and a

different size adapter fitting.

Gas supply line coupling must be 34" (864 mm) to 37"

(940 mm) from the floor.

If your washer/dryer has been converted to use LP gas, " LP

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON

®†

tape.

Must include a shutoff valve:

In the U.S.A.:

An individual manual shutoff valve must be installed within

six (6) feet (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSI Z223.1.

In Canada:

An individual manual shutoff valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual

manual shutoff valve be installed within six (6) feet (1.8 m)

of the dryer.

The l

ocation should be easy to reach for opening and closing.

Burner input requirements

Elevations up to 10,000 ft (3,048 meters):

The design of this washer/dryer is certified by CSA

International for use at altitudes up to 10,000 ft (3,048 m)

above sea level at the Btu rating indicated on the model/serial

number plate. Burner input adjustments are not required when

the dryer is operated up to this elevation.

Elevations above 10,000 ft (3,048 meters):

When installed above 10,000 ft (3,048 m), a 4% reduction of

the burner Btu rating shown on the model/serial number plate

is required for each 1,000 ft (305 m) increase in elevation.

Gas supply pressure testing

The washer/dryer must be disconnected from the gas supply

piping system during pressure testing at pressures greater

than ½ psi.

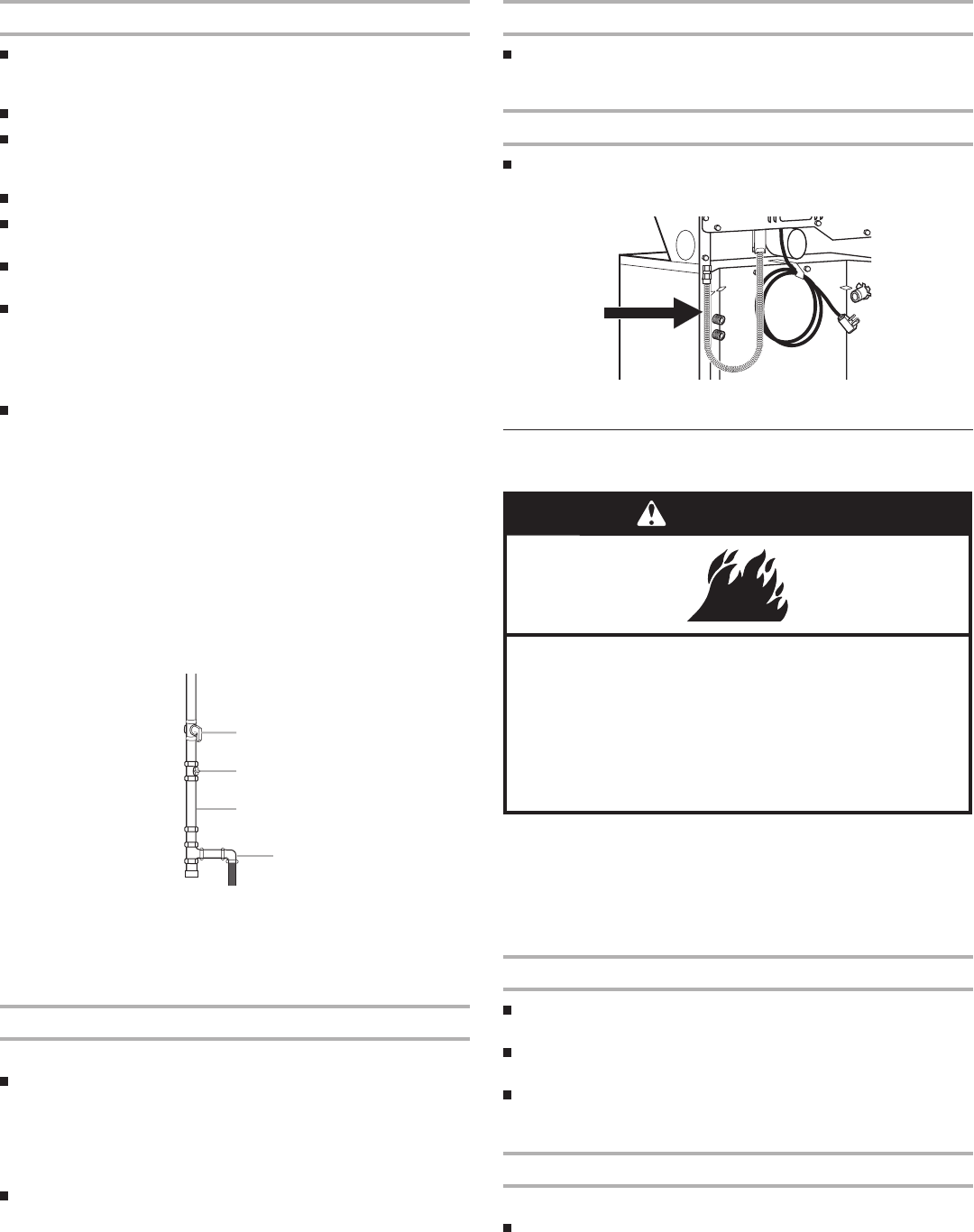

Dryer gas connection

This washer/dryer is equipped with its own permanent,

flexible gas connector, design-certified by CSA International,

for connecting the washer/dryer to the gas supply line.

Flexible gas connector

Venting Requirements

WARNING: To reduce the risk of fire, this washer/dryer

MUST BE EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building.

If using an existing vent system

Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance. Only

rigid or flexible metal vent shall be used for exhausting.

If this is a new vent system

Vent material

Use a heavy metal vent. Do not use plastic or metal foil vent.

A. Gas shutoff valve

B. " NPT plugged tapping

C. ½" NPT gas supply line

D. Gas supply line coupling 34" (864 mm) min.

to 37" (940 mm) max. from floor

†

®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

A

B

C

D

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

1

⁄8

1

⁄2

3

⁄8

3

⁄8

1

⁄8