SDAP Nomad Dryer with AP1 Control

Reference Manual (PN: 882.00281.00) for

Complete Operation and Installation Instructions

(Available online at www.sterlco.com)

Sterling Part No: 682.92636.03

2900 S. 160

th

Street • New Berlin, WI 53151 USA Bulletin No: DH1-315.02

Tel. 262.641.8610 • Fax 262.641.8653

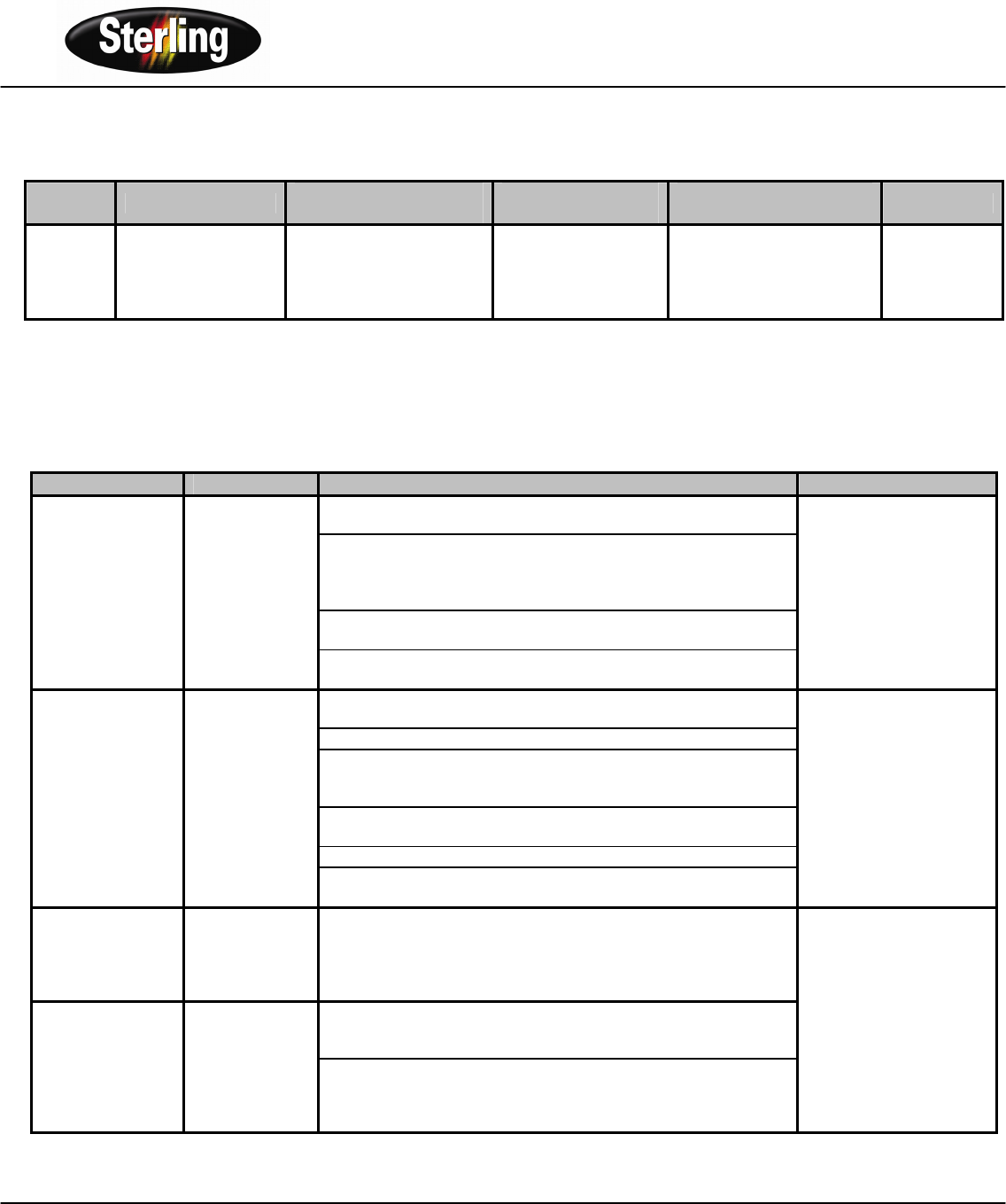

Spare Parts List

Model Filter

Desiccant

Replacement Beads

Regeneration

Thermocouple

Process

Thermocouple

Gasket

SDAP

25/50/100

Standard

Temperature

– Part # W00052474

High Temperature –

Part # 161.00194.00

13 X Beads – Part #

W00018051

25 ONLY – 96” Long

– Part # A0568474

50/100 ONLY – 96”

Long

– Part # A0543758

15’ Long (Braided Design)

– Part # A0568466

72” Long (Braided Design)

– Part # A0568473

Standard and

High

Temperature

– Part #

A0566839

Troubleshooting - Quick Guide

Alarm Message Cause Corrective Action Dryer Status

Make sure the process air filter is clean. Clean or replace if

necessary.

Make sure all the hose connections and all the components of

the dryer have proper seals on them (i.e. desiccant tanks, heater

box, filters, after-cooler). Tighten the connections and replace

any damaged seals.

Make sure the regeneration timing cycle matches the specs. If

not, contact the Service Department.

High Dew Point

The dew point

reading has

exceeded the

dew point alarm

set point.

Desiccant may be contaminated and blocking the air flow. Check

desiccant, replace if necessary.

Dryer Normal:

- Process blower ON.

- Process heaters ON.

- Regen heaters ON.

- Alarm Message ON.

- Alarm horn is OFF.

Make sure the process filter is clean. Clean or replace if

necessary.

Double check the alarm set point is at 35° F.

Check the positioning of the thermocouple inside the air inlet of

the drying hopper. The tip of the thermocouple should be

centered in the tube, and not touching any metal part of the tube.

The drying temperature set point is lower than dryer capabilities.

Check the dryer specs.

Make sure all the hose connections are tight.

Process High

Temp

The process

temperature

has exceeded

the alarm set

point.

Make sure the regeneration timing cycle matches the specs. If

not, contact Service department.

Dryer Shuts Down:

- Process blower OFF.

- Process heaters OFF.

- Regen heaters OFF.

- Alarm light is ON.

- Alarm horn is ON.

Valve Positioning

Fault

The limit switch

on the valve

may not have

been wired

correctly.

The switch is indicating the incorrect desiccant tank is in

regeneration. Check the wiring of the switch against the wiring

diagram. Make sure all the wire connections are tight.

Limit switch may be out of position. Re-adjust the switch so it

trips when it is at the high position, and avoids touching the cam

when it is at the low position.

Valve Motor

Override

The valve has

made enough

rotations and

the correct

position of the

valve was not

detected.

Limit switch may be faulty. Replace the switch and make sure

the wires are connected correctly.

Dryer Shuts Down:

- Process blower OFF.

- Process heaters OFF.

- Regen heaters OFF.

- Alarm light is ON.

- Alarm horn is ON.

Note: Refer to the main manual and wiring diagram for a complete Spare Parts List