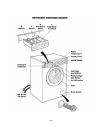

PLUMBING (Water Inlet)

The straight end of these hoses should be connected to the supply (Fig. 4).

The 90° angled end of these h

oses should be connected to the inlet valves

on the back of the machine, using one of the washers to make a water

tight seal on

each connection. The couplings should be tightened by hand,

a tool should only be used if a leak occurs. Do not use excessive fo

rce

(see M, Fig. 5).

The Inlet valves are color

-

coded:

Red = Hot

White = Cold

It is possible to run the machine on cold water

only, but a water supply

must be connected to each inlet valve. To do this we suggest you use "F"

connector, supplied with the

washer

-

dryer (see N, Fig. 6).

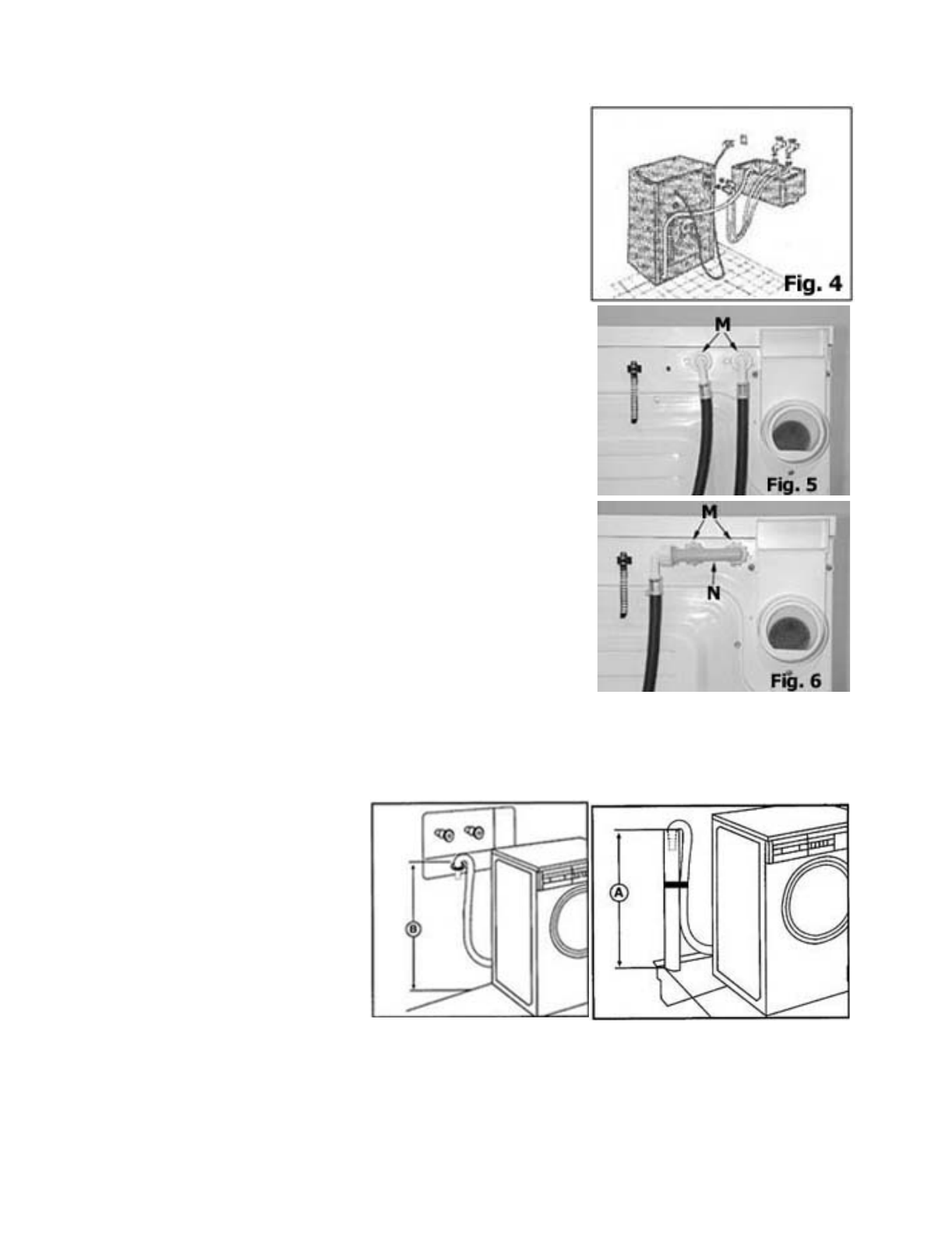

PLUMBING (Water Outlet)

You should carefully position the drain hose to avoid kinks and ensure

proper drainage of the water.

The outlet end of the drain hose must be at least 20" (50 cm) above the

base of the machine. At t

his point it is possible for the water to be

discharged into a sink, standpipe or drainpipe.

No more than 6" of the drain

hose should insert into a standpipe. Assure

an air break is available to prevent the machine from siphoning in a

stan

d

pipe.

IMPORTANT

Make sure the drain hose is not kinked and the water flow is not

restricted.

Standpipe Drain System:

When a standpipe installation is used it

must be at least 1

¼

" (3.2 cm) in diameter

with a minimum carr

y away capacity of 7

gallons (26 liters) per minute.

Wall or Floor Standpipe Drain:

Top of standpipe must be at least 25" (62

cm) high and no higher than 34" (86 cm)

from bottom of washer (A & B).

Page 3