Inspection and Installation

27

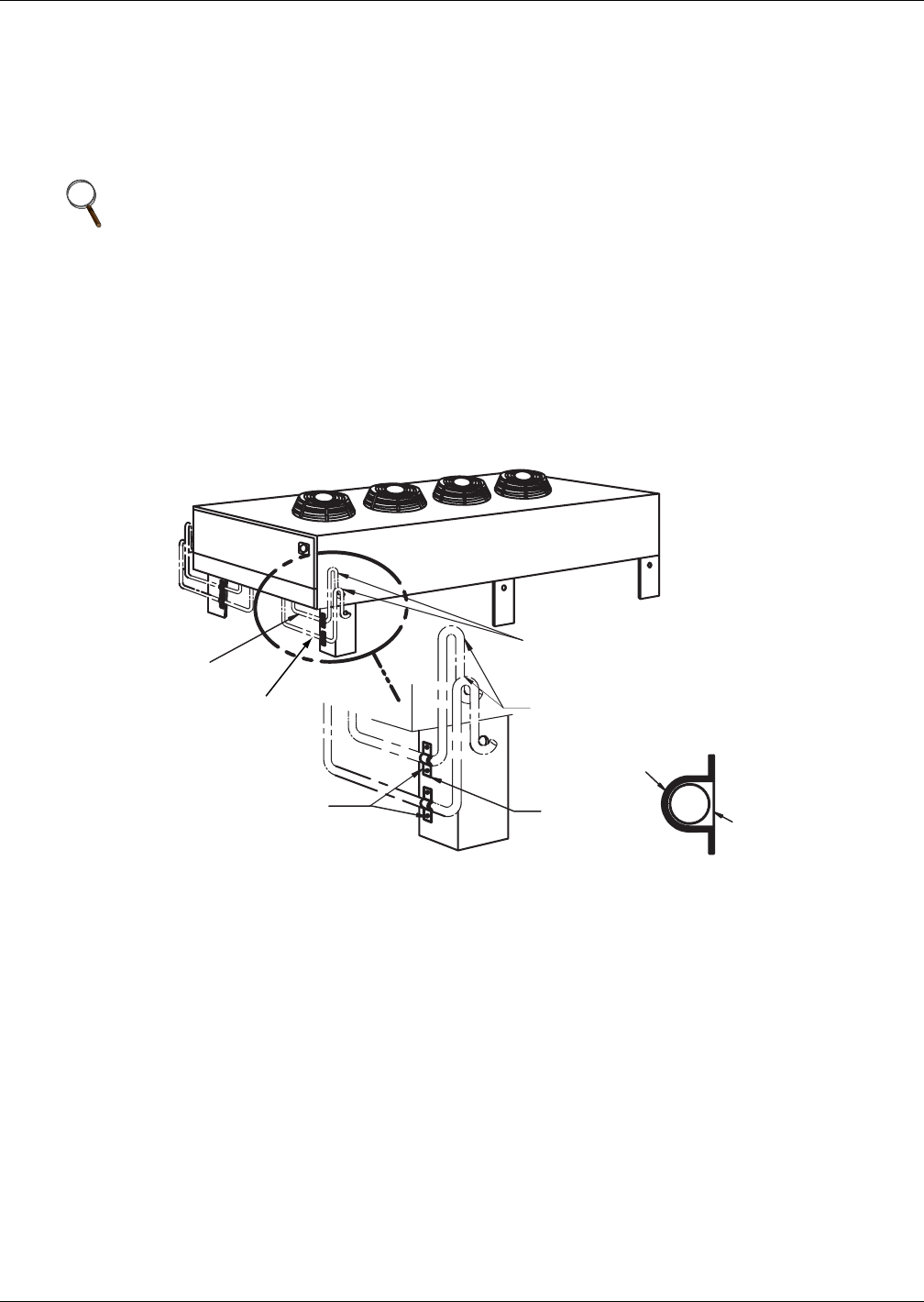

3.9.2 Field Piping Installation

One discharge line and one liquid line must be field-installed for each circuit of the indoor unit and

the outdoor condenser(s). Dual circuit condensers are available for most dual circuit indoor unit appli-

cations. Refer to Figures 22, 23 and 24 below for additional field-installed piping needed at the con-

denser. This piping is needed for proper system performance and for installation/interconnecting

receivers and head pressure control valves for Lee-Temp systems.

Figure 22 VFD and Fan Speed Control condenser piping

NOTE

Keep the evaporator unit and condenser closed with their factory charge of dry nitrogen while

all field piping is installed. Keep the field piping clean and dry during installation, and do not

allow it to stand open to the atmosphere.

When all the field interconnecting piping is in place, vent the condenser’s dry nitrogen charge

and connect to the field piping. Finally, vent the evaporator unit’s dry nitrogen charge and

make its piping connections last.

Follow all proper brazing practices, including a dry nitrogen purge to maintain system

cleanliness.

Fasten liquid and hot gas lines

to leg using flat surface clamps

with isolators ( field-supplied).

Support field piping separately

to avoid coil damage and loss of charge.

Traps to Extend Above Base of

Coil by a Minimum of 7-1/2" (190mm)

Inverted Traps

(Field Supplied)

Entering Hot

Gas Line

Leaving

Liquid Line

See

Detail

A-A

DPN001065

Rev. 0

Detail A-A

Metal

Clamp

Isolator