Typical Full Load Chart

Load Loading Load Loading

Type Suggestion Type Suggestion

Mixed 2 double or Heavy 2 pair work pants

Load 1 king size sheet Work 3 work shirts

4 pillowcases Clothes 1 coverall

6 T-shirts 3 pair jeans

6 pair shorts

2 boy's shirts

2 blouses

6 handkerchiefs

This washer provides all cold water rinses. Laboratory analysis

indicates no rinse problems with either phosphate or powdered

non-phosphate detergents. Modern fabrics (synthetic knits and

blends, permanent press) benefit from a cold rinse because of

improved wrinkle resistance. See the following charts.

Water Usage

The following chart shows approximate hot and cold water usage

with no clothes in the washer basket (measurements in gallons).

Type Cycle Selected Hot Water Cold Water

Hot Wash - Cold Rinse 18.6 19.9

Warm Wash - Cold Rinse 9.2 29.3

Cold Wash - Cold Rinse O 40

Water Savings Option

Adjusting the water level switch allows you to save

10% water usage.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

To adjust the water level switch:

1. Unplug washer or disconnect power.

2. Remove 2 screws on the console at left and right side

on bottom.

3. Pull console forward, then tilt it back.

4. Squeeze locking tab on water level switch and turn 45°.

5. Use pliers and turn shaft on the water level switch 45°.

6. Replace water level switch.

7. Swing console down into place, push toward the rear.

8. Replace 2 console screws.

9. Plug in washer or reconnect power.

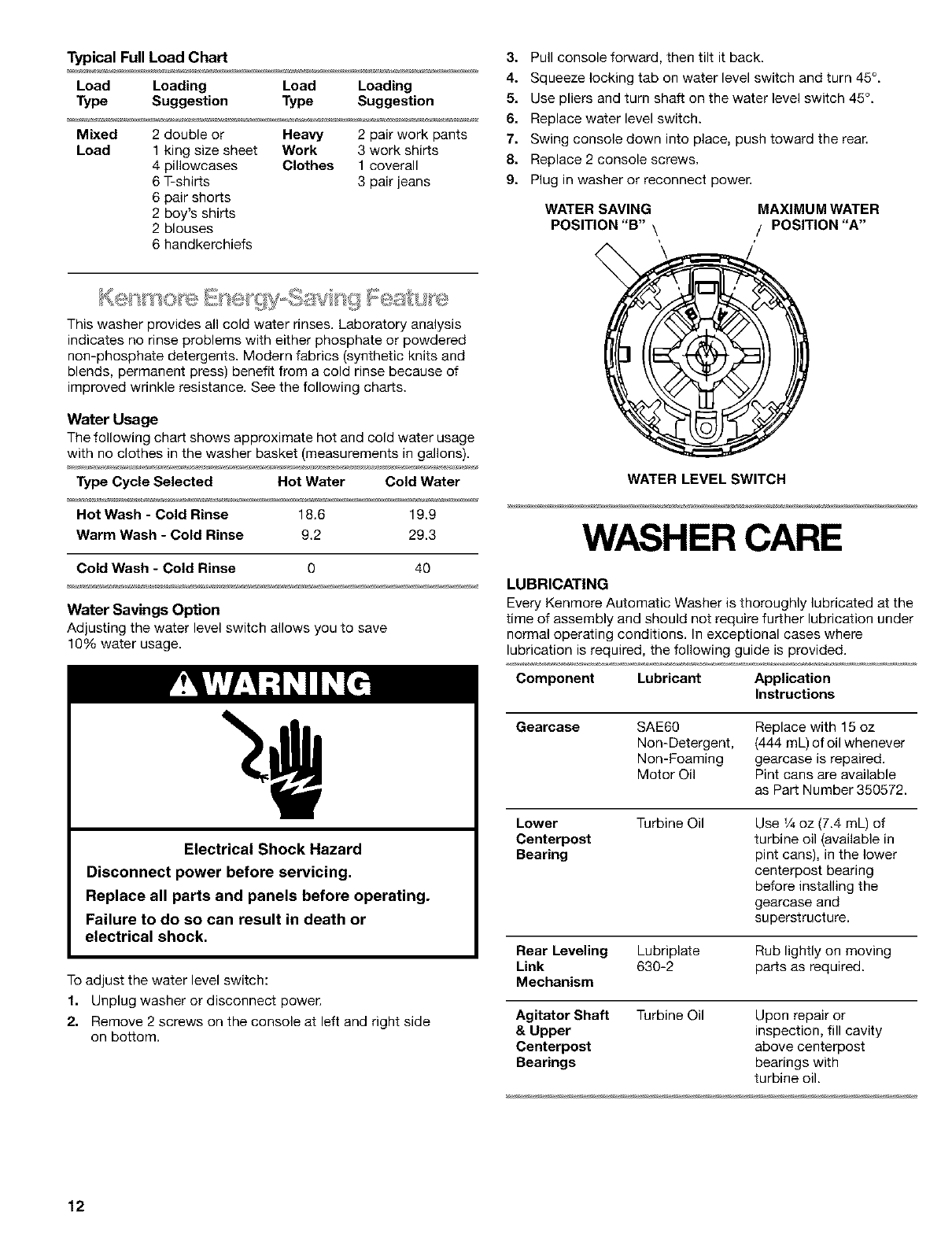

WATER SAVING

POSITION "B" \

MAXIMUM WATER

/ POSITION"A"

WATER LEVEL SWITCH

WASHER CARE

LUBRICATING

Every Kenmore Automatic Washer is thoroughly lubricated at the

time of assembly and should not require further lubrication under

normal operating conditions. In exceptional cases where

lubrication is required, the following guide is provided.

Component Lubricant Application

Instructions

Gearcase SAE60

Non-Detergent,

Non-Foaming

Motor Oil

Replace with 15 oz

(444 mL) ofoil whenever

gearcase is repaired.

Pint cans are available

as Part Number 350572.

Lower

Ceaterpost

Bearing

Turbine Oil

Use V4oz (7.4 mL) of

turbine oil (available in

pint cans), in the lower

centerpost bearing

before installing the

gearcase and

superstructure.

Rear Leveling Lubriplate Rub lightly on moving

Link 630-2 parts as required.

Mechanism

Agitator Shaft Turbine Oil Upon repair or

& Upper inspection, fill cavity

Centerpost above centerpost

Bearings bearings with

turbine oil.

12