Installation - Electrical

The C series Dryers require a 220/240 Volt 1 phase and neutral 50-60 Hz supply. A flying lead is installed on the

dryer for convenience. The cable core colours are:

BrownLive

BlueNeutral

Green / YellowEarth

If the unit is connected to a junction box, receiving its supply from another source (e.g., auxiliary contacts of a

main starter, or a relay), then it is important that electrical protection is provided by means of a suitably rated

H.R.C. fuse located in the line. Installation must comply with the latest edition of IEE Wiring Regulations, Safety

Standards and any Local Codes of Practice that apply.

Installation - Mechanical

Connect the compressed air pipework to the Dryer using approved pipe and fittings of the correct rating and

type. To ensure damage does not occur to internal pipework and components during the connection process,

remove access cover(s) and if necessary support the internal pipework / components. Please ensure that ALL

shut off valves are fully open before starting unit.

The drain connection should be connected to a suitably sized drain line and piped to a suitable oil / water

separator prior to drain.

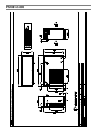

Installation Recommendations

The compressed air pipework should incorporate sufficient shut-off valves to enable the dryer to be by-passed

and/or disconnected in the event of repair or replacement.

A purge valve should also be fitted at a convenient point to enable the air pressure to be released safely and

gradually before undoing any connections.

A suitably sized pressure safety device should be fitted to prevent over-pressurisation of the compressed air

dryer.

If the compressor pumps intermittently, or the total air demand does not exceed the total flow rate of the

compressor, the dryer MUST be installed downstream of the receiver.

If the receiver is sized to permit wide fluctuations on air demand or if peak demand exceed compressor

maximum flow rate, the dryer SHOULD be installed upstream of the receiver.

A minimum of 5 micron (Denco recommend 1 micron) pre-filter must be fitted to remove impurities from the air

prior to it entering the dryer. Additional filtration may be required downstream of the dryer subject to the site

requirements.

1 Air Compressor

2 Receiver

3 Safety Valve

4 Shut off valve

5 Pre-filter (1 micron)

6 Refrigerant Dryer

7 After-filter

(0.01 micron, dust filter &

activated carbon as required)