If all rigid metal duct cannot be used, then flexible

all-metal venting can be used, but it will reduce the

maximum recommended duct length. In special

installations when it is impossible to make a

connection with the above recommendations, then

UL-listed clothes dryer transition duct

may be used as

transition venting between the dryer and wall

connection only. The use of this ducting will affect

drying time.

If flexible transition duct is necessary, only UL-listed duct

identified for use with clothes dryers is approved.

The following directions must be followed.

• Use the shortest length possible.

• Stretch the duct to its maximum length.

• Do not crush or collapse.

• Never use transition duct inside the wall, flooring,

ceiling or inside the dryer.

• Avoid resting the duct on sharp objects.

• Venting must conform to local building codes.

12

Use only 4

″

(10.2 cm) diameter (minimum) rigid metal

duct for best performance, or flexible metal duct.

Use

approved vent hood which has swing-out dampers

that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to

prevent drafts and the entrance of insects and

rodents. To avoid restricting the outlet, maintain a

minimum of 12″ (30.5 cm) clearance between the

vent hood and the ground or any other obstruction.

If all rigid metal duct cannot be used, then flexible

all-metal venting can be used, but it will reduce the

maximum recommended duct length. See

Additional

Installation Instructions

following.

WARNING: The following are specific requirements

for proper and safe operation of your dryer. Failure

to follow these instructions can create excessive

drying times and fire hazards.

DO NOT use plastic flexible duct to exhaust the

dryer. Excessive lint can build up inside exhaust

system and create a fire hazard and restrict air

flow. Restricted air flow will increase drying times.

If your present system is made up of plastic duct or

metal foil duct, replace it with rigid or flexible

metal duct. Ensure the present duct is free of any

lint prior to installing dryer duct.

The dryer exhaust system MUST BE EXHAUSTED

TO THE OUTSIDE of the dwelling.

DO NOT

allow combustible materials (for example:

clothing, draperies/curtains, paper) to come in

contact with exhaust system.

The dryer MUST NOT be exhausted into a gas vent,

chimney, a wall, a ceiling, a common duct with a

kitchen exhaust or any concealed space of a

building which can accumulate lint, resulting in

a fire hazard.

DO NOT

exceed the length of duct pipe or

number of elbows allowed in the

Maximum Length

charts. Lint can accumulate in the exhaust

system, plugging the system and creating a fire

hazard, as well as increasing drying times.

DO NOT

screen the exhaust ends of the vent

system, nor use any screws or rivets to assemble

the exhaust system. Lint can become caught in

the screen, on the screws or rivets, clogging the

duct work and creating a fire hazard as well as

increasing drying times. Use an approved vent

hood to terminate the duct outdoors, and seal

all joints with duct tape. All male duct pipe

fittings

MUST

be installed downstream with

the flow of air.

EXPLOSION HAZARD.

Do not install the dryer

where gasoline or other flammables are kept

or stored. If the dryer is installed in a garage,

it must be a minimum of 18″ (45.7 cm) above

the floor. Failure to do so can result in death,

explosion, fire or burns.

Provide an access for inspection and cleaning of

the exhaust system, especially at turns. Inspect

and clean at least once per year.

Do not obstruct incoming or exhausted air.

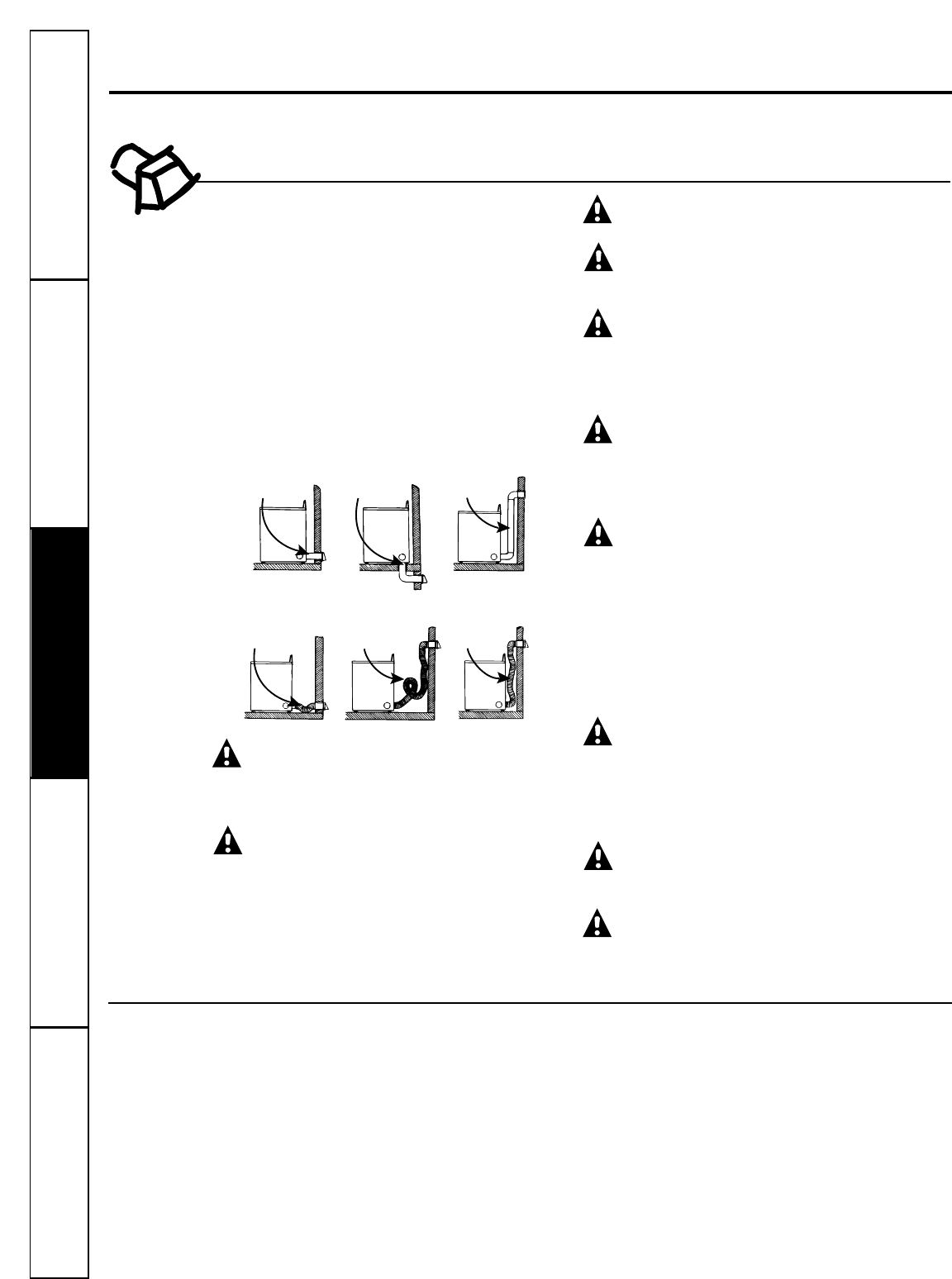

Correct

Incorrect

Do

Do

Do

Don’t

Don’t

Don’t

Additional Installation Instructions

Exhaust System Requirements

Exhausting the dryer.

Read these instructions completely and carefully.

Consumer Support Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation Instructions