INSTALLATION – GAS DRYER

IMPORTANT - OBSERVE ALL GOVERNING CODES

Dryer must be levelled and rest firmly on the floor.

Dryer must be exhausted to the outdoors.

FOR YOUR SAFETY

What to do if you smell gas

• Do not try to light appliance.

• Do not touch any electrical switch ; do not use

any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you can not reach your gas supplier, call fire

department.

• Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

GAS CONNECTION INFORMATION

Installation must conform with local Gas Codes and

with CAN/CGA-B149, Natural Gas Installation Code.

Some local codes restrict installation of gas appliances

in garages. They must be 45 cm (18”) off the ground

and protected by a barrier from vehicules.

GAS BURNER ORIFICE

This gas dryer is equipped with a Valve & Burner

Assembly for use ONLY WITH ONE TYPE OF GAS.

Using the appropriate kit, your local service

organization can convert this dryer for use with the

alternate fuel.

Use kit WE25M35 to convert from Natural Gas to LP

Gases (Propane).

Use kit WE25M36 to convert from LP Gases to Natural

Gas.

WARNING: CONVERSION SHALL BE CARRIED

OUT IN ACCORDANCE WITH THE

REQUIREMENTS OF THE PROVINCIAL

AUTHORITIES HAVING JURISDICTION AND/OR

ACCORDANCE WITH THE REQUIREMENTS OF

THE CAN/CGA B149.1 AND B149.2

INSTALLATION CODE.

GAS SUPPLY

• Supply line is to be 12.7 mm (1/2 in) rigid pipe.

(9.53 mm (3/8 in) copper tubing may be used if the

dryer is operated on propane gas) and equipped with

an accessible shutoff within 6 feet (2 m) from, and in

the same room with the dryer. Increase pipe size for

runs longer than 20 feet (7 m).

• During pressure test:

– When test pressure is in excess of 1/2 PSIG

(3.45kPa), disconnect dryer and its individual

shutoff valve from gas supply line prior to test.

– When test pressure is equal to or less than 1/2 PSIG

(3.45kPa), close the dryer shutoff valve prior to test.

• A 3.18 mm (1/8 in) National Pipe Taper thread

plugged tapping, accessible for test gauge connection,

must be installed immediately upstream of the gas

supply connection to the dryer. Contact your local gas

utility should you have questions on the installation of

the plugged tapping.

• Pipe dope must be resistant to the action of propane

and applied sparingly to all male threads.

• If local codes permit, it is recommended the dryer be

connected to the gas supply with approved semi-rigid

metal tubing or listed connectors.

LEAK TEST

Check all connections for leaks with soapy solution or

equivalent. Leak test solutions must not contain ammonia

which could cause damage to brass fittings or pipe.

CAUTION: NEVER USE AN OPEN FLAME TO

TEST FOR GAS LEAKS.

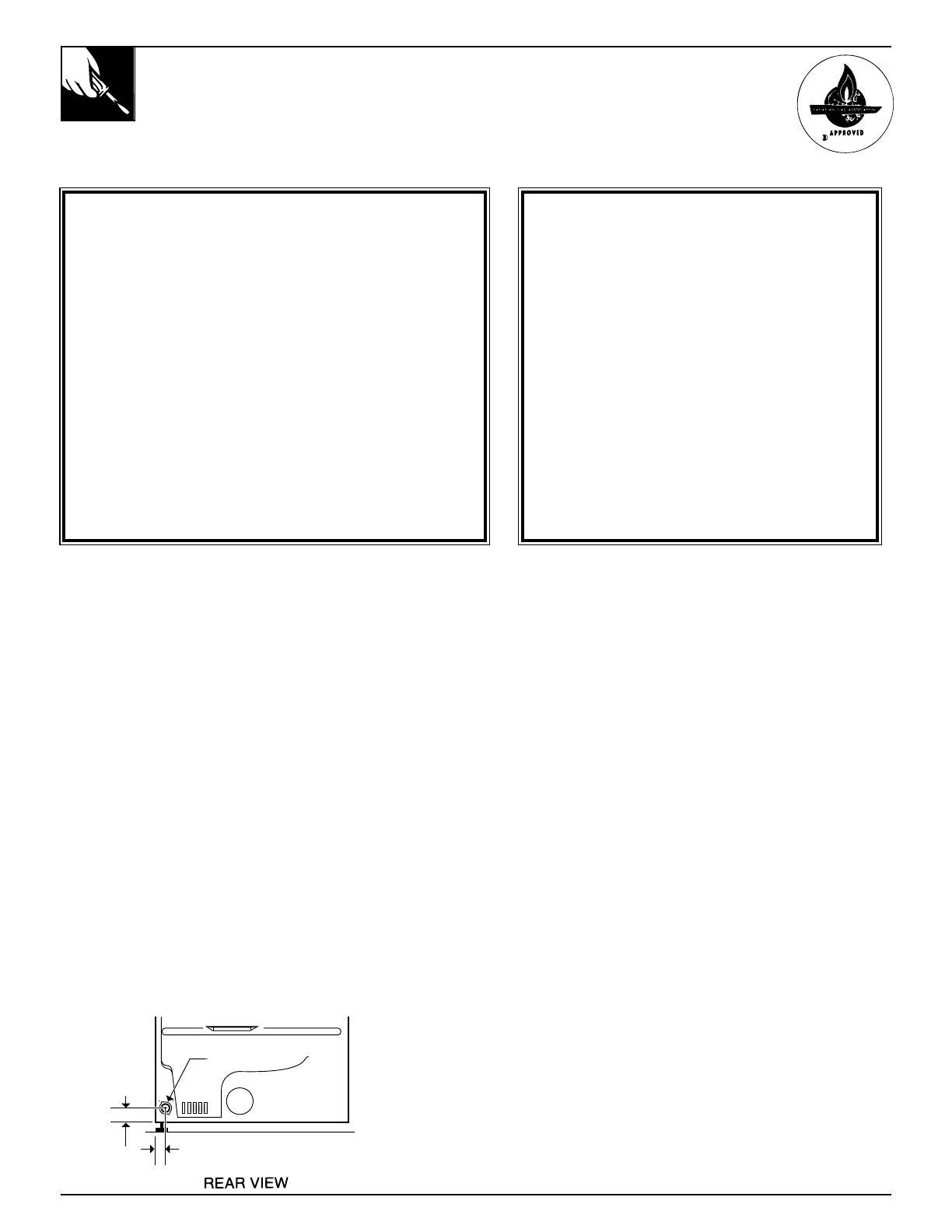

51mm

(2")

66 mm

(2 5/8")

MALE THREAD GAS SUPPLY

9.52 mm (3/8")

8