SERVICE

When servicing unit, shut off all electrical power to the

unit to avoid shock hazard or injury from rotating parts.

Cleaning — Inspect unit interior at the beginning of each

cooling season and as operating conditions require.

CONDENSER COIL — Inspect coil monthly. Clean con-

denser coil annually and as required by location or outdoor-

air conditions.

Clean coil as follows:

1. Turn off unit power.

2. Remove and save top panel screws on condensing unit.

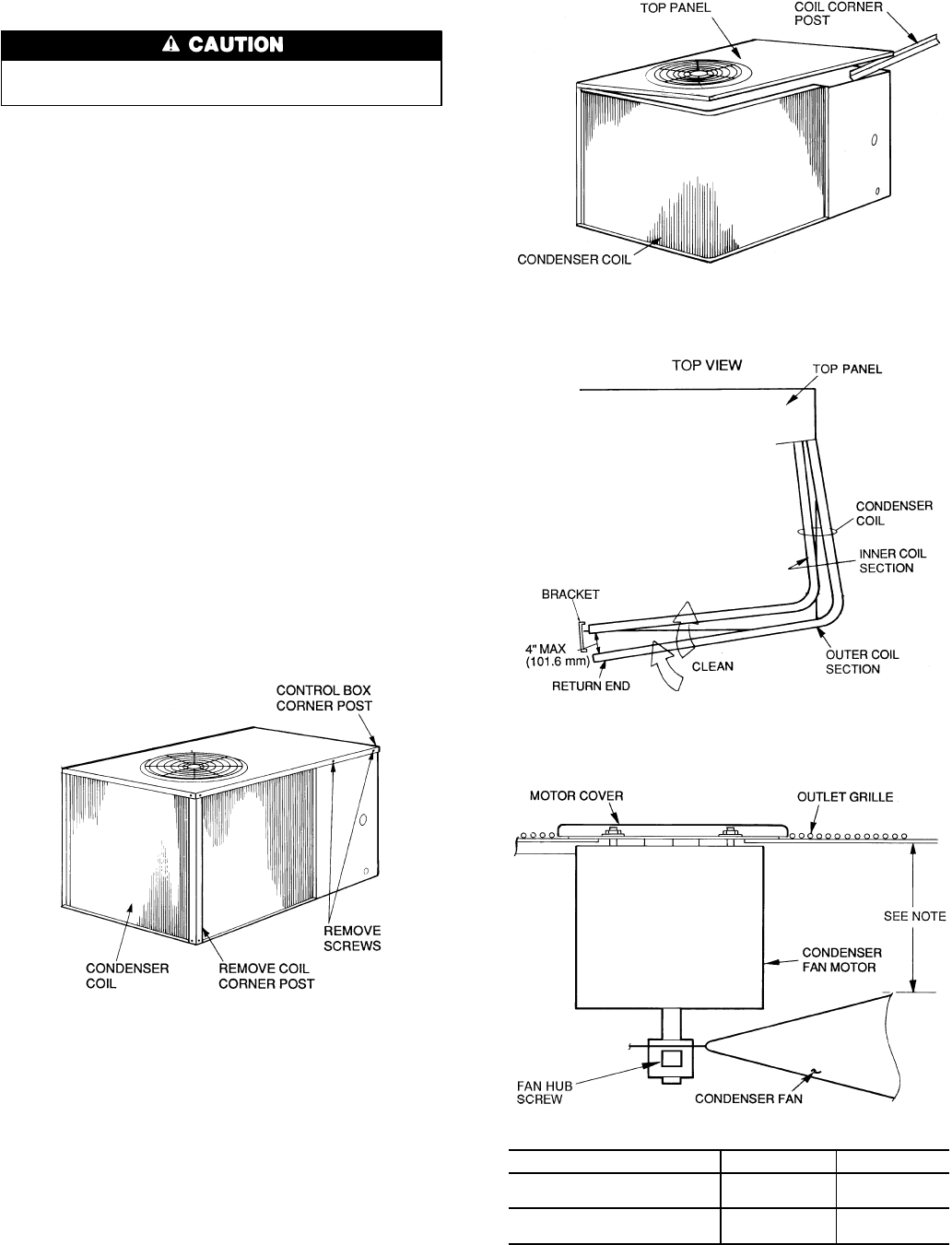

3. Remove condenser coil corner post. See Fig. 10. To hold

top panel open, place coil corner post between top panel

and side panel. See Fig. 11.

4. Remove bracket holding coil sections together at return

end of condenser coil. Carefully separate the outer coil

section 3 to 4 in. (75 to 100 mm) from the inner coil sec-

tion. See Fig. 12.

5. Use a water hose or other suitable equipment to flush down

between the 2 coil sections to remove dirt and debris. Clean

the outer surfaces with a stiff brush in the normal manner.

6. Reposition the outer coil section, and secure the coil sec-

tions together by reinstalling the brackets removed in

Step 4.

7. Remove the coil corner post from between the top panel

and side panel.

8. Install the coil corner post and replace all screws re-

moved in Step 2.

Lubrication

COMPRESSORS — Each compressor is charged with cor-

rect amount of oil at the factory. For additional information

on 38AKS units, refer to the Oil Charge section on page 10.

FAN MOTOR BEARINGS — Fan motor bearings are of

the permanently-lubricated type. No further lubrication is

required.

Condenser-Fan Adjustment (Fig. 13)

1. Shut off unit power supply.

2. Remove condenser-fan assembly (grille, motor, motor cover,

and fan).

3. Loosen fan hub setscrews.

Fig. 11 — Propping Up Top Panel

Fig. 12 – Separating Coil Sections

NOTE: Fan height adjustments are as follows:

UNIT in. mm

38AK007 (60 Hz)

All 50-Hz Units

4.50 114

All 60-Hz Units

(Except 38AK007)

6.42 163

Fig. 13 — Condenser-Fan Adjustment

Fig. 10 — Cleaning Condenser Coil

11