START-UP

Preliminary Checks

1. Field electrical power source must agree with unit name-

plate rating.

2. Check that all internal wiring connections are tight and

that all barriers, covers, and panels are in place.

3. Ensure all service valves are open. On 38AKS units, be

sure all compressor service valves are backseated.

4. Verify that compressor holddown bolts for units

38AKS have been loosened and that flat/snubber wash-

ers can be rotated by applying finger pressure (snug, but

not tight).

5. Verify compressor crankcase heater is securely in place.

Crankcase heater must operate for at least 24 hours be-

fore start-up. The 38AK unit size 007 does not require

a crankcase heater.

6. Note that compressor oil level is visible in the sight glass

(38AKS units only).

7. Check for leaks in refrigerant system by using soap bubbles

and/or electronic leak detector.

8. Check that liquid line solenoid valve is located at

evaporator coil as shown in Filter Drier and Moisture

Indicator section, page 6.

9. Check voltage imbalance as shown in Table 5,

Note 2.

10. Check that both outdoor and indoor units are properly

mounted in accordance with installation instructions and

applicable codes.

Evacuate and Dehydrate — Evacuate and dehy-

drate entire refrigerant system by use of the methods

described in Carrier GTAC II, Module 4, System Dehydra-

tion. Evacuate system down to 500 microns and ensure vacuum

hold for 15 minutes. If vacuum does not hold, pressurize sys-

tem and locate leak and repair.

Refrigerant Charge — Refer to Carrier GTAC II,

Module 5, Charging Recovery, Recycling, and Reclamation.

NOTE: Use of a Carrier Totalclaim refrigeration recovery

unit is highly recommended when recovering refrigerant.

Unit panels must be in place when unit is operating dur-

ing charging procedure.

Unit is shipped with holding charge only. Weigh in 7 lb

(3 kg) of R-22 to start unit.

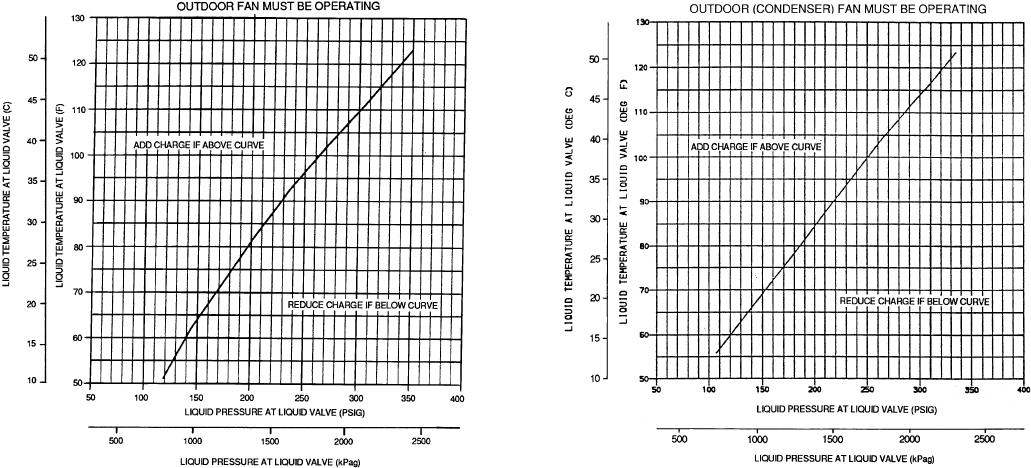

CHARGE COOLING — Use Cooling Charging Charts,

Fig. 8A or 8B and 9A or 9B. Vary refrigerant until the

conditions of the chart are met. Note that charging charts are

different from type normally used. Charts are based on charg-

ing the units to the correct subcooling for the various oper-

ating conditions. Accurate pressure gage and temperature

sensing device are required. Connect the pressure

gage to the service port on the liquid line service valve. Mount

the temperature sensing device on the liquid line, close to

the liquid line service valve and insulate it so that outdoor

ambient temperature does not affect the reading. Indoor air-

flow must be within the normal operating range of the unit.

Operate unit a minimum of 15 minutes. Ensure pressure

and temperature readings have stabilized. Plot liquid pres-

sure and temperature on chart and add or reduce charge to

meet curve. Adjust charge to conform with charging chart,

using liquid pressure and temperature to read chart.

Compressor Overload — This overload interrupts power

to the compressor when either the current or internal motor

winding temperature becomes excessive, and automatically

resets when the internal temperature drops to a safe level.

This overload may require up to 60 minutes (or longer) to

reset. If the internal overload is suspected of being open, dis-

connect the electrical power to the unit and check the circuit

through the overload with an ohmmeter or continuity tester.

Cycle-LOC™ Device — When high-pressure or low-

pressure fault occurs, the Cycle-LOC device will protect the

system by not allowing the compressor to start.

Low-Pressure/Loss-of-Charge Switch (LPS) —

When the liquid line pressure drops below 7 psig (48 kPa),

the LPS opens 24-v power to the compressor contactor and

stops the compressor. When the pressure reaches 22 psig

(152 kPa), the switch resets and the compressor is allowed

to restart.

Fig. 8A — Cooling Charging Chart — 38AK007

(60 Hz)

Fig. 8B — Cooling Charging Chart — 38AK007

(50 Hz)

9