9

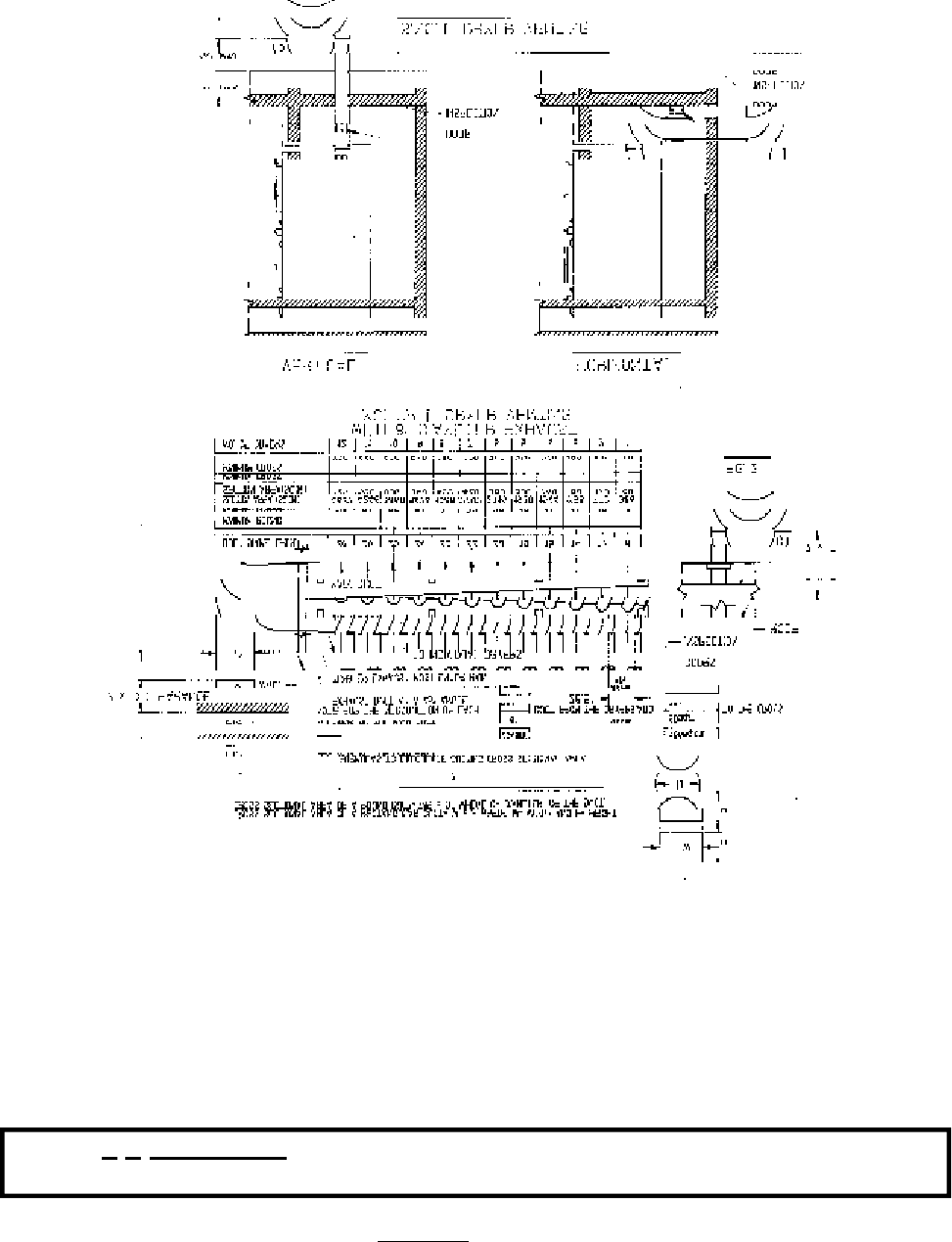

The main duct may be any shape of cross section area, so long as the minimum cross section area is

provided. Figure 1, shown above, shows the minimum cross section area for multiple dryer venting. These

figures must be increased if more than twelve (12) dryers are connected to the same main (common) duct,

if the main duct end run is unusually long (20 feet [6.1 meters] or more), or if there are numerous elbows in

the main duct end run. In calculating duct size, the cross section area of a square or round duct must be

increased 20 percent (20%) for each additional 20 feet (6.1 meters). The diameter of a round exhaust

should be increased 10 percent (10%) for each additional 20 feet (6.1 meters). Each 90º elbow is equivalent

to an additional 15 feet (4.57 meters), and each 45º elbow, an additional 10 feet (3.05 meters).

NOTE: It is recommended that no more than four (4) dryers be connected to the same exhaust

duct.

It is suggested that the use of 90º turns be avoided; use 30º or 45º angles instead. The ductwork should be

smooth inside, with no projections from sheet metal screws or other obstructions, which will collect lint.

When adding ducts, the duct to be added should overlap the duct to which it is to be connected. Also,

inspection doors should be installed at strategic points in the exhaust ductwork for periodic inspection and

cleaning.