Setting the Process Air Temperature

When setting the process air temperature, consult with the resin manufacture for the

recommended drying temperature.

To change the process air temperature set point with the dryer running:

• Press

to raise the set point to the temperature you want.

• Press

to lower the set point to the temperature you want.

Restoring the Process Air Temperature Controller (E5CN) to Factory Settings

If the preset parameters on the controller have been tampered with and it no longer properly

controls temperature, you can restore the controllers to the factory setup. Call the Service

Department for detailed instructions.

E5CN Operating Parameters

The E5CN controller has several mode selections. Within each mode are numerous

parameters that can be set.

The factory has set the security level to protect the critical parameters from being accidentally

changed. Below is an explanation of the operating modes you will have access to and on the

following page are the manufacturers’ default settings.

Available E5CN Modes

Operation Level

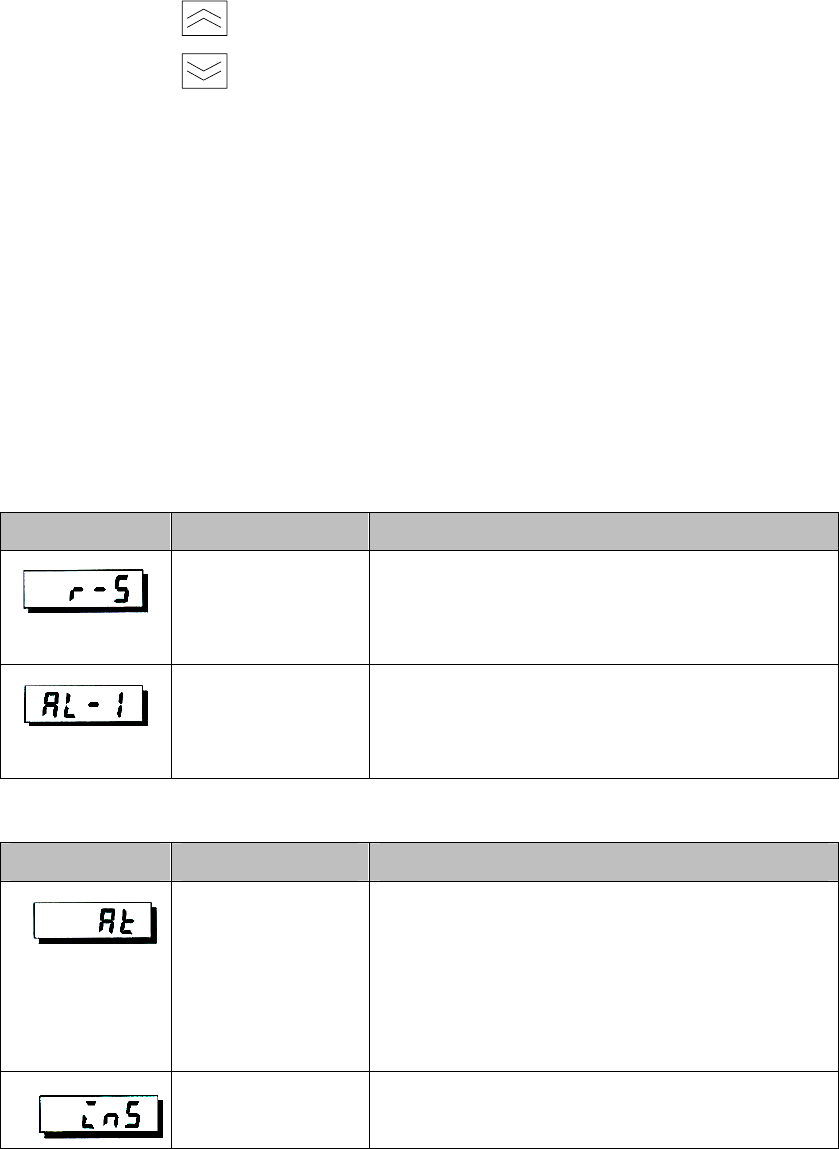

Indicator Name Description

Run/Stop Mode

(r-S)

When “RUN” is selected, the control is running.

When “STOP” is selected, the control is stopped.

When the control is stopped, the STOP display

lights. The default is set to “RUN.”

Alarm Value 1

Mode (AL-1)

(35°F)

This setting is used to indicate how many degrees

the process temperature will be allowed to exceed

the set point temperature. An alarm output will de-

energize the heaters and blower.

Adjustment Level

Indicator Name Description

Auto-Tune Mode

(At)

See Page 19 of Chapter 3 for instructions on how

to Auto-Tune your dryer.

Note: Although the controller is calibrated at

the factory, the manufacturer

recommends that the unit be Auto-

Tuned prior to dryer startup.

Temperature Input

Shift Mode (TnS)

This setting is used to offset an error between the

set point and the actual temperature. The entire

input range is shifted by a set figure

15, 30, & 60 cfm Compact Dryers 23