Electrical

requirements

Now start...

Use duct tape to seal all joints.

with dryer in laundry area.

Take tape off front corners of dry

For mobile home installation, the dryer must have

an outside exhaust. If you exhaust the dryer through

the floor and the area under your mobile home is

enclosed, the exhaust

system must terminate

outside the enclosed area.

Extension beyond the

enclosure will prevent lint

and moisture build-up under

the mobile home.

Electrical Shock Hazard

l

Electrical ground is required on this

appliance.

l

If cold water pipe is interrupted by plastic,

non-metallic gaskets or other insulating

materials, Do Not use for grounding.

l

Do Not ground to a gas pipe.

l

Do Not modify the power supply cord plug.

If it does not fit the outlet, have a proper

outlet installed by a qualified electrician.

l

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the neutral or

grounding circuit could result in an electrical

shock.

l

Do Not use an extension cord with this

appliance.

l

Check with a qualified electrician if you are

in doubt as to whether the appliance is

properly grounded.

Failure to flow these instructions could result

in serious injury or death.

I I

E-l

Open dryer and remove the literature and

, parts packages. (If dryer has a drying rack

it should be removed also.) Remove all

parts from the plastic packages. Line these up next

to your tools so each part is there when you need it.

Check to see that you have these parts:

The exhaust duct can be routed up, down, left, right

or straight out of the back of the dryer. Detailed

space requirements can be found in “Recessed and

closet installation instructions” on the back cover.

Metal flexible duct should be fully extended and

supported when the dryer is in final position. DO

NOT KINK OR CRUSH THE DUCT. The metal

flexible duct must be completely open to allow

adequate exhaust air to flow.

is used, it is recommended that qualified

electrician determine that the grounding path is

adequate.

A 120-volt, 60-Hz, AC-only, 15or 20-ampere fused

electrical supply is required. Time-delay fuse or

circuit breaker is recommended. It is recommended

that a separate circuit serving only this appliance be

provided.

An exhaust hood should cap the exhaust duct to

prevent exhausted air from returning into dyer. The

outlet of the hood must be at least 12 inches from

the ground or anything else that may be in the path

of the exhaust.

Recommended

grounding method

A 4-inch outlet hood is preferred; however, a

2-l/2-inch outlet may be used with short systems

only. (This outlet creates greater back pressure

than other hood types.)

0

3

Remove the tape that holds the drum to the

l

cabinet. (Some dryer drums are not taped

for shipping.) Move the drum by hand to

make certain all tape has been removed. Wipe the

interior of the drum thoroughly with a damp cloth

before using the dyer. Remove the tape from the lint

For your personal safety, this appliance must be

grounded. This appliance is equipped with a power

supply cord having a 3-prong grounding plug. To

minimize possible shock hazard, the cord must be

plugged into a mating 3-prong

3-prong grounding-

3-prong grounding -

type wall receptacle, plug

grounded in

grounding, type wee

accordance with the Power

National Electrical

Code, ANSVNFPA

70 - latest edition, and

all local codes and

ordinances. If a mating

prong

The exhaust outlet is located at the bottom center

back of the dryer.

Detailed space requirements can be found in the

“Recessed and closet installation instructions” on the

back cover and on back panel of dyer.

wall receptacle is not

available, it is the personal responsibility and

obligation of the customer to have a properly

grounded 3-prong wall receptacle installed by a

qualified electrician.

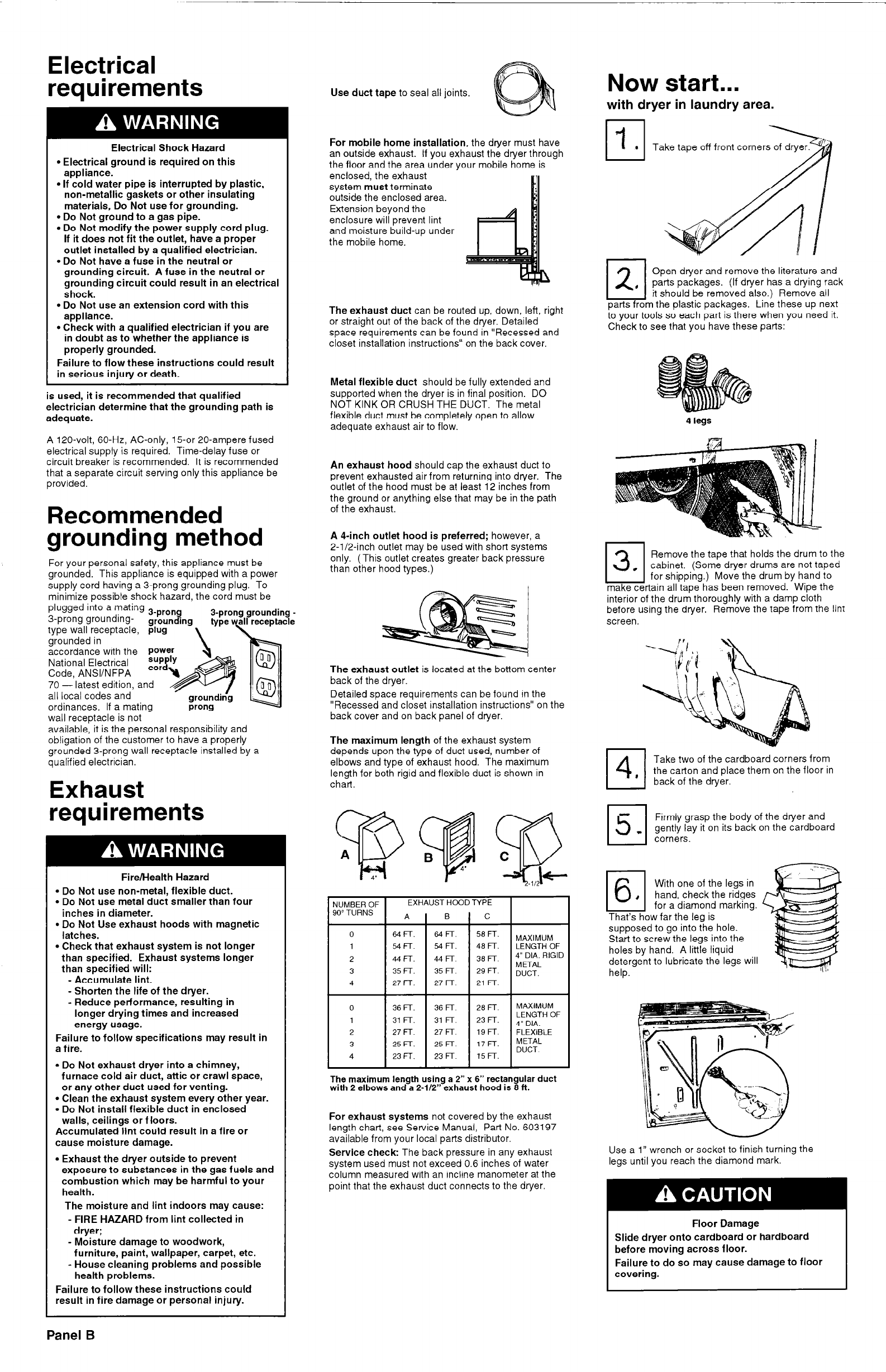

The maximum length of the exhaust system

depends upon the type of duct used, number of

elbows and type of exhaust hood. The maximum

length for both rigid and flexible duct is shown in

chart.

u

4

Take two of the cardboard corners from

*

the carton and place them on the floor in

back of the dryer.

Exhaust

requirements

Firmly grasp the body of the dyer and

gently lay it on its back on the cardboard

corners.

0

6

With one of the legs in

4

hand, check the ridges

for a diamond marking.

That’s how far the leg is

supposed to go into the hole.

Start to screw the legs into the

holes by hand. A little liquid

detergent to lubricate the legs will

help.

Fire/Health Hazard

l

Do Not use non-metal, flexible duct.

l

Do Not use metal duct smaller than four

inches in diameter.

l

Do Not Use exhaust hoods with magnetic

latches.

l

Check that exhaust system is not longer

than specified. Exhaust systems longer

than specified will:

- Accumulate lint.

- Shorten the life of the dryer.

- Reduce performance, resulting in

longer drying times and increased

energy usage.

Failure to follow specifications may result in

a fire.

l

Do Not exhaust dryer into a chimney,

furnace cold air duct, attic or crawl space,

or any other duct used for venting.

l

Clean the exhaust system every other year.

l

Do Not install flexible duct in enclosed

walls, ceilings or floors.

Accumulated lint could result in a fire or

cause moisture damage.

l

Exhaust the dryer outside to prevent

exposure to substances in the gas fuels and

combustion which may be harmful to your

health.

The moisture and lint indoors may cause:

- FIRE HAZARD from lint collected in

dryer;

- Moisture damage to woodwork,

furniture, paint, wallpaper, carpet, etc.

- House cleaning problems and possible

health problems.

Failure to follow these instructions could

result in fire damage or personal injury.

NUMBER OF

TYPE

~ c

58FT.

MAXIMUM

48 FT.

LENGTH OF

38 FT.

4” DIA. RIGID

METAL

29 FT.

DUCT.

21 FT.

28 FT.

MAXIMUM

23 FT.

LENGTH OF

4” DIA.

19Fr

FLEXIBLE

17 FT.

METAL

DUCT

15Fr.

EXHAUST HO01

A B

644. 64 FT.

54Fr

54 FT.

t

44FT. 44 Fr

35 FT. 35 FT.

27 FT. 27 FT.

36 FT. 36 FT.

31 FT. 31 FT.

27 FT. 27 IT

25 FT. 25 FT.

23 FT. 23 FT.

The maximu

R length using a 2”

c 6” rectangular duct

with 2 elbow ; and a 2-112” exhal

st hood is 8 ft.

For exhaust systems not covered by the exhaust

length chart, see Service Manual, Part No. 603197

available from your local parts distributor.

Service check: The back pressure in any exhaust

system used must not exceed 0.6 inches of water

column measured with an incline manometer at the

point that the exhaust duct connects to the dryer.

Use a 1” wrench or socket to finish turning the

legs until you reach the diamond mark.

Floor Damage

Slide dryer onto cardboard or hardboard

before moving across floor.

Failure to do so may cause damage to floor

covering.

Panel B