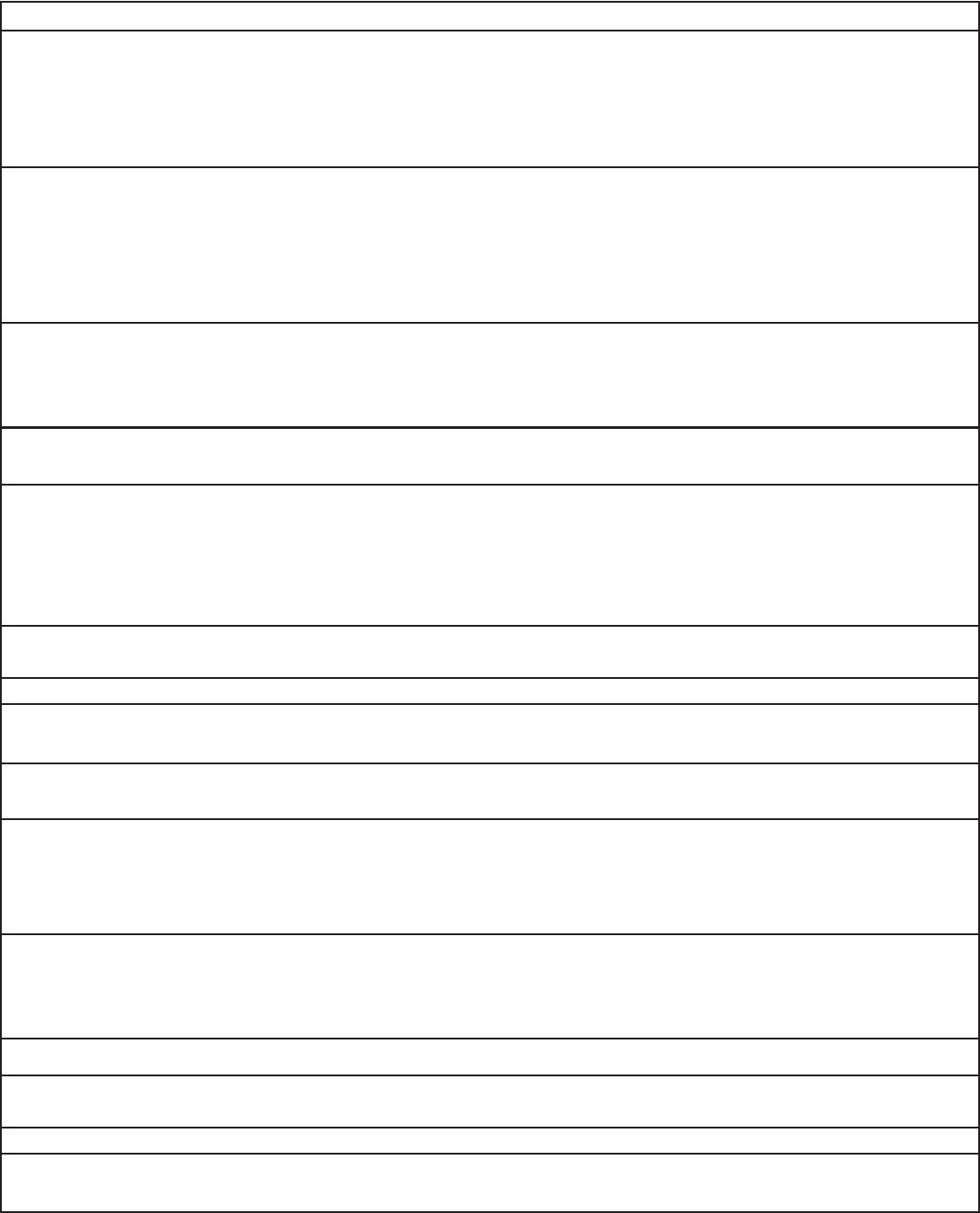

3

Problem Possible Cause Repair Procedure

1g. Timer

1g. Set to start of regular wash cycle. Test for

115 vac between high side of hot and cold water

inlet valves and common (low) side of water

inlet valves. If not present, the timer may be

defective.

1h. Temperature Selector Switch

1h. Set to Start of the regular wash cycle. Set

water temperature selector to WARM/COLD.

Test f or 115 vac between high side of hot and

cold water inlet valves and common (low) side

of water inlet valves. If not present the selector

switch may be def ective .

1i. Water inlet valves.

1i. If 115 vac is present across a water inlet

valve coil and water pressure is present, the

machine should f ill. If not, the valve may be

defective.

2. Fills, won't

agitate

2a. Belt. 2a. Check belt, adjust tension.

2b. Electronic Control Module

2b. Test signals at the Control Module. See

Testing the Electronic Control Module. If correct,

replace the Control. If test on terminals 1 to 7

fail, replace timer. If tests on terminal 8, 9, 12

through 15 fail, replace motor.

2c. Motor

2c. Check motor resistance. See Testing Drive

motor.

3. Won't drain 3a. Filter 3a. Remove, clean, and replace filter.

3b. Drain hose 3b. Check for kinks or blockage.

3c. Drain

3c. Drain standpipe inlet m ore than 36" above

the floor. Blocked drain. (direct connection)

3d. Pump

3d. With power of f , run pump cooling impeller

manually to check for jamming. If pump does

not turn freely, disassemble, remove foreign

objects, and reassemble.

3e. Timer

3e. Set timer to REGULAR SPIN. Test for 115

vac across the pump terminals. If present, the

pump may be defective. If not present, timer

may be defective.

4. Won't spin. 4a. Belt. 4a. Check belt, adjust tension.

4b. Electronic Control Module

4b. Test Control Module in accordance with the

appropriate procedure.

4c. Overloaded 4c. Reduce load size.

4d. Wet load 4d. Check water inlet valves for leaks. See #3