16

Solutions to Common Problems

Common Drying Problems

Many drying problems involve poor cleaning results, poor soil and stain removal, residues of lint and

scum, and fabric damage. For satisfactory drying results, follow these suggestions provided by The

Soap and Detergent Association.

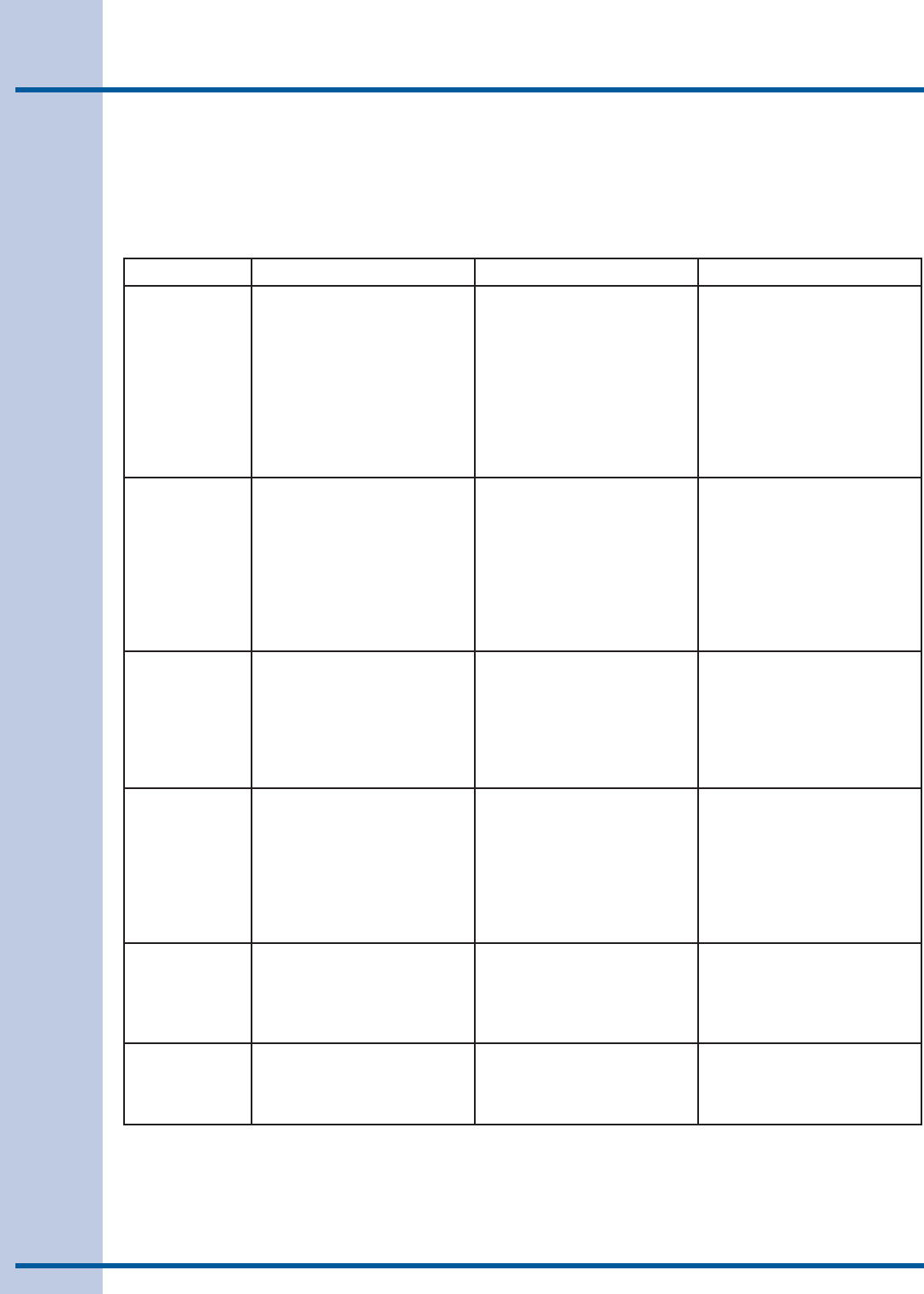

PROBLEM POSSIBLE CAUSES SOLUTIONS PREVENTIVE MEASURES

Greasy, oily

stains

Fabric softener sheet.• Rub fabric softener stains •

with bar soap. Rinse and

rewash.

Add a few bath towels •

to small loads for proper

tumbling.

Some “silk-like” fabrics •

should be air dried.

Use proper drying tempera-•

ture.

Place fabric softener sheet •

on top of load before start-

ing the dryer.

Lint Overloading.•

Overdrying causes static •

electricity.

Lint screen not clean when •

cycle began.

Lint is attached to “pills.”•

Reduce load size and •

rewash using liquid fabric

softener in the fi nal rinse.

Or, add a fabric softener •

sheet and tumble without

heat.

Use lint brush or roller to •

remove lint.

Do not overload dryer.•

Use fabric softener in •

washer or dryer to reduce

static electricity.

Remove items when they •

are slightly damp to avoid

overdrying.

Check that lint fi lter is clean •

and in place.

Pilling

(Fibers break

off, ball up and

cling to fabric.)

Overdrying.• Use a lint brush or shaver to •

remove pills.

Use fabric softener to lubri-•

cate fi bers.

When ironing, use spray •

starch or fabric fi nish on

collars and cuffs.

Turn items inside out to •

reduce abrasion.

Shrinking Temperature too high.•

Overdrying.•

Irreversible condition.• Follow fabric care label •

directions.

If shrinking is a concern, •

check load often.

Remove items while slightly •

damp and hang or lay fl at to

complete drying.

Block knits into shape.•

Wrinkling Overloading.•

Leaving items in dryer after •

cycle ends.

Reduce load size and •

tumble at medium or low

heat for 5-10 minutes.

Remove items immediately. •

Hang or fold.

Do not overload dryer.•

Remove items as soon as •

cycle ends.

Isolated wet

spots on fabrics

after completed

Steam cycle

Low water line pressure in •

home is not suffi cient to

atomize incoming water

during Steam cycle

Check water line pressure• Ensure water line pressure •

is minimum of 30 psi. Do

not exceed 120 psi.