Pressure Washer Maintenance

Check and Clean Inlet Screen: Examine inlet screen

on pump inlet fitting. Clean if clogged; replace if torn.

Check High Pressure Hose: High pressure hose can

develop leaks from wear, kinking, abuse. Inspect hose

each time before use. Check for cuts, leaks, abrasions

or bulging of cover, and damage or movement of

couplings. If any of these conditions exist, replace

hose immediately.

Check Chemical/Soap Hose: Examine the chemical/

soap hose and clean if clogged. Hose should fit tightly

on pump fitting. Check for leaks and tears. Replace

filter or hose if either is damaged.

Check Gun and Wand: Examine hose connection to

gun making sure it is secure. Test trigger by pressing it

and making sure it springs back into place when you

release it.

Pump Maintenance (Changing Pump Oil)

The pump on your pressure washer was shipped from

the factory with oil. The oil in your pump must be

changed every 50 hours.

• Run engine until it runs out of fuel. Otherwise, fuel

can leak out, creating a fire/explosion hazard, when

you tip engine.

• Disconnect spark plug wire and keep it away from

spark plug.

• Drain engine oil. See Changing Oil on page 8.

_CAUTION: Used oil is a hazardous waste

product. Dispose of used oil properly. Do not

discard with household waste. Check with your

local authorities for safe disposal/recycling

faci t es.

• Tilt unit and drain pump oil into appropriate

container.

• Fill pump with 8 ounces of R&O 150 oil. NOTE: tf

unable to find R&O 150 oil, use 30W non-deter-

gent oil.

• Replace oil drain plug and tighten securely.

• Refill engine with oil and fuel. See Engine Oil on

page 8.

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these

steps:

• Set up the pressure washer as described in

ASSEMBLY section and connect the water supply.

• Remove the wand extension from the spray gun.

• Pull the trigger on the gun and hold.

To remove the contaminants from the pump,

follow these steps:

• Set up the pressure washer as described in

ASSEMBLY section, connect the water supply.

• Remove the wand extension from the spray gun.

• Start the engine according to instructions in the

OPERATION section.

• Pull the trigger on the gun and hold.

• When the water supply is steady and constant,

disengage trigger and refasten the wand exten-

sion.

Engine Maintenance

Check Oil Level

• Oil level should be checked prior to each use or at

least every 5 hours of operation. To check oil see

Engine Oil on page 8.

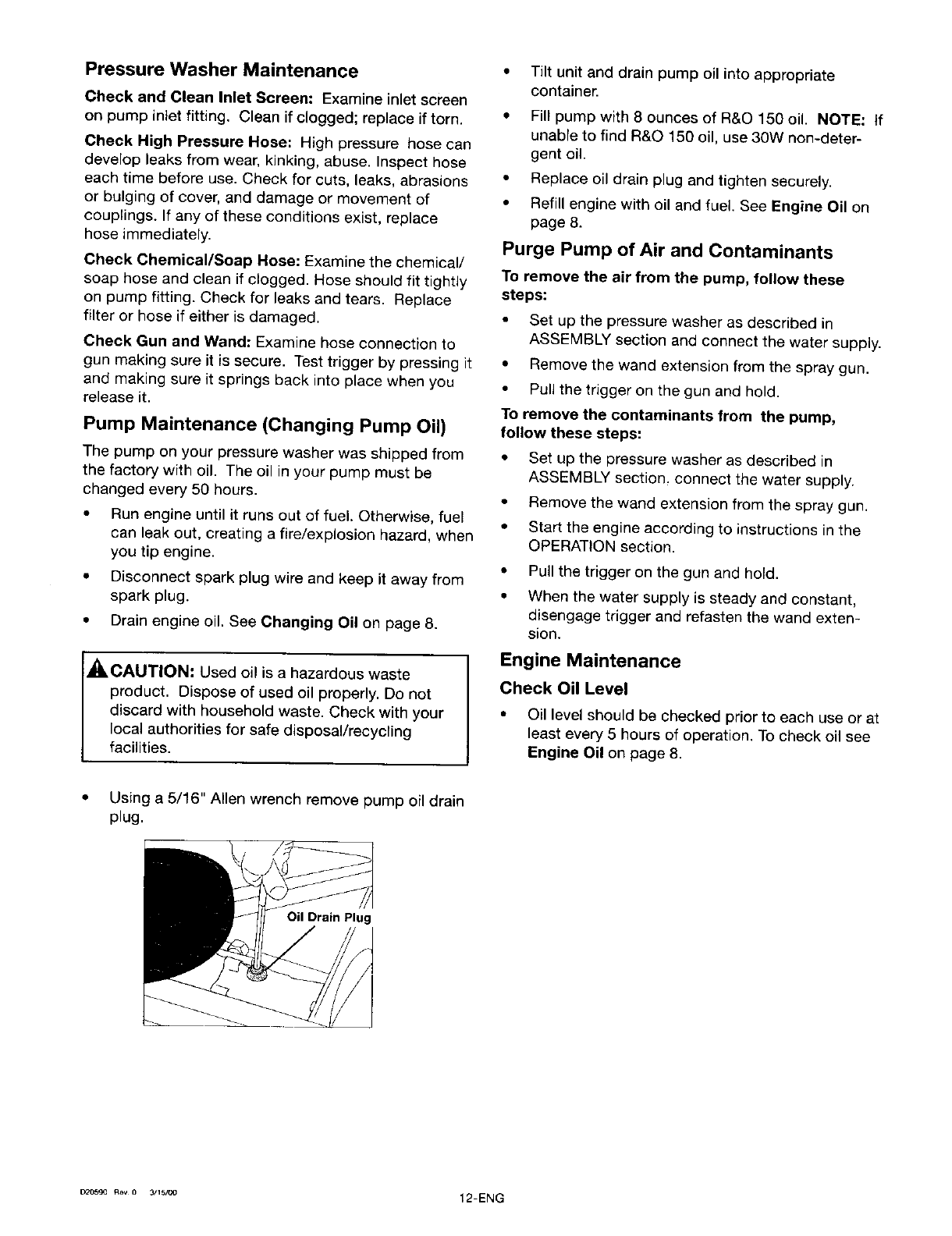

• Using a 5/16" Allen wrench remove pump oil drain

plug.

Oil Drain Plug

ce059eRev0 3_1_ce 12-ENG