© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

17

AJ1031

Location Requirements

NOTE: If a forklift is used to move press, exercise

care that forklift arms are inserted under frame

and DO NOT CONTACT ANY OPERATING

MECHANISM.

Moving press to installation location while still

attached to skid is recommended. However, press can

be removed from skid before moving.

Removing Press from Skid

Unscrew four shipping screws from attaching holes.

Using a forklift, lift press and remove skid.

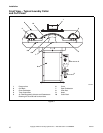

Press should be located in an area that provides a

minimum of 24 inches (61 cm) between press and any

structure.

NOTE: Above dimensions are considered

MINIMUM working and maintenance dimensions

and SHOULD BE INCREASED if possible.

Space between front of table and closest structure

should be determined by work requirements, but in no

case should be less than 30 inches (76.2 cm).

Foundation Requirements

Install press on a solid, level floor such as concrete.

NOTE: Installation on a wooden floor can cause

machine to shift, which WILL result in

MISALIGNMENT of heads and bucks and

DAMAGE to both press and garments.

Floor should be capable of supporting 125 pounds per

square foot (56.7 kg). Remove all floor covering

material (tile, wood, carpeting, etc.) from press

mounting area.

Uncrating

Remove front cover from press and use a hammer to

knock out shipping brace.

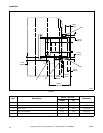

Installing Anchor Bolts and

Levelling Press

After press is in position, attach and level it to floor

with four anchor bolts (obtain locally). Using the

frame base anchor bolt holes as a template, drill four

holes in floor. Holes must be drilled deep enough to

properly install bolts in accordance with

manufacturer’s instructions. Securely tighten anchor

bolts.

Ensure press is level front and back, as well as left and

right. Place a spirit level on top of frame. If press is not

level, raise and lower corners as required. Place

sufficient shims between press frame and floor. Shims

should be sized to make maximum contact with floor

and frame to distribute weight evenly. Use industrial

grout if necessary.

NOTE: Prior to bolting to floor, shim press frame

to eliminate rocking.

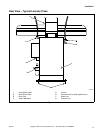

Connecting Steam Supply and

Returns

(Refer to Figure 8)

NOTE: Clean out ALL pipe lines BEFORE

connecting them to press. Failure to properly install

suitable traps and check valves AND supply correct

steam pressure WILL REDUCE operating

efficiency.

Steam supply connected to press must have a constant

pressure of 115 psig (7.9 bar).

The following steps outline the procedure for

connecting steam supply and return lines to press:

1. Run a 1/2 NPT steam supply to steam supply

connection with suitable black iron pipe, elbows,

strainer, ball valve and union.

NOTE: A MINIMUM 3 inch (7.62 cm) riser should

be installed off supply header to minimize water in

steam supply to press.

NOTE: It is recommended that a steam strainer be

installed between steam supply and press.

2. Install two suitable 1/2 NPT unions, steam traps,

check valves and one ball valve between steam

return connections and steam return lines.

NOTE: Cast iron inverted bucket traps are

recommended. Size traps according to steam

pressure and consumption found in Specifications

in Table 1.

To avoid possible serious injury:

• ALWAYS be careful to AVOID spring-

loaded components when working

inside press.

• Installation MUST be performed ONLY by

qualified service personnel.

W336

WARNING