7

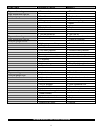

10. Oil Sightglass:

The oil sightglass is found on the side of the crankcase on accessible scroll compressors to provide a

visual means of checking the oil level. The oil must be checked only while the compressor is in operation.

During compressor operation the oil sight glass should be approximately 1/2 full.

11. Refrigerant Liquid Line Filter-Dryer:

A liquid line filter-dryer is used on all AIR/TAK refrigerated dryers. The purpose of the filter-dryer is to eliminate

the possibility of moisture, or other foreign particles, from moving throughout the system. These particles, such

as carbon, can cause early compressor failure. The filter-dryer also has a high quality desiccant which is

capable of removing moisture to a very low point and can also remove a reasonable quantity of acid.

12. Water Pressure Switch (Water Cooled only):

This control is used only on dryers equipped with water cooled condensers. The purpose of this switch is to

assure that adequate water pressure and flow is available to the refrigerant condenser.

13. Desuperheating Valve (D-1250 and larger):

This valve is used on larger capacity dryers. Due to the larger refrigerant charges associated with these

models the addition of the desuperheating valve is necessary. The valve's purpose is to provide liquid

refrigerant to desuperheat hot discharge gas used to establish suction gas pressure.

14. High Temperature Control:

This control is used to protect the compressor from excessive return gas temperature. During the start-up

phase, the high temperature light may be lit until the refrigeration system reaches its normal running

temperatures and pressures. (See Start-up; Section I).

During normal operation on Models 320 SCFM through 2000 SCFM, this control will activate the high

temperature light when return gas temperatures become excessive. Immediate action is required by the

customer to turn off the dryer.

On models 2500 SCFM and above, this control will activate the high temperature light and will also

open the electrical circuit on the compressor and shutdown the dryer. The dryer will not restart without

the customer turning the selector switch to off and then back on. Customer evaluation should be

undertaken to determine the cause of the high temperature condition.

After start-up, the high temperature light condition may result from: plugged or dirty condensers, high ambient,

high compressed air inlet temperatures or high compressed air flow.

15. Start Timer:

Standard on 2500 SCFM and larger dryers, This timing device is used in conjunction with the High

Temperature Control in item 14.

During start-up, this device will temporarily energize the compressor(s) electrical circuit. The start timer is

factory set to allow adequate time for the refrigeration system to reach normal suction gas temperatures. If

normal suction gas temperatures do not occur within the factory set time, the compressor will shut-down. This

shut-down may be caused by conditions as noted in item 14 above.