10

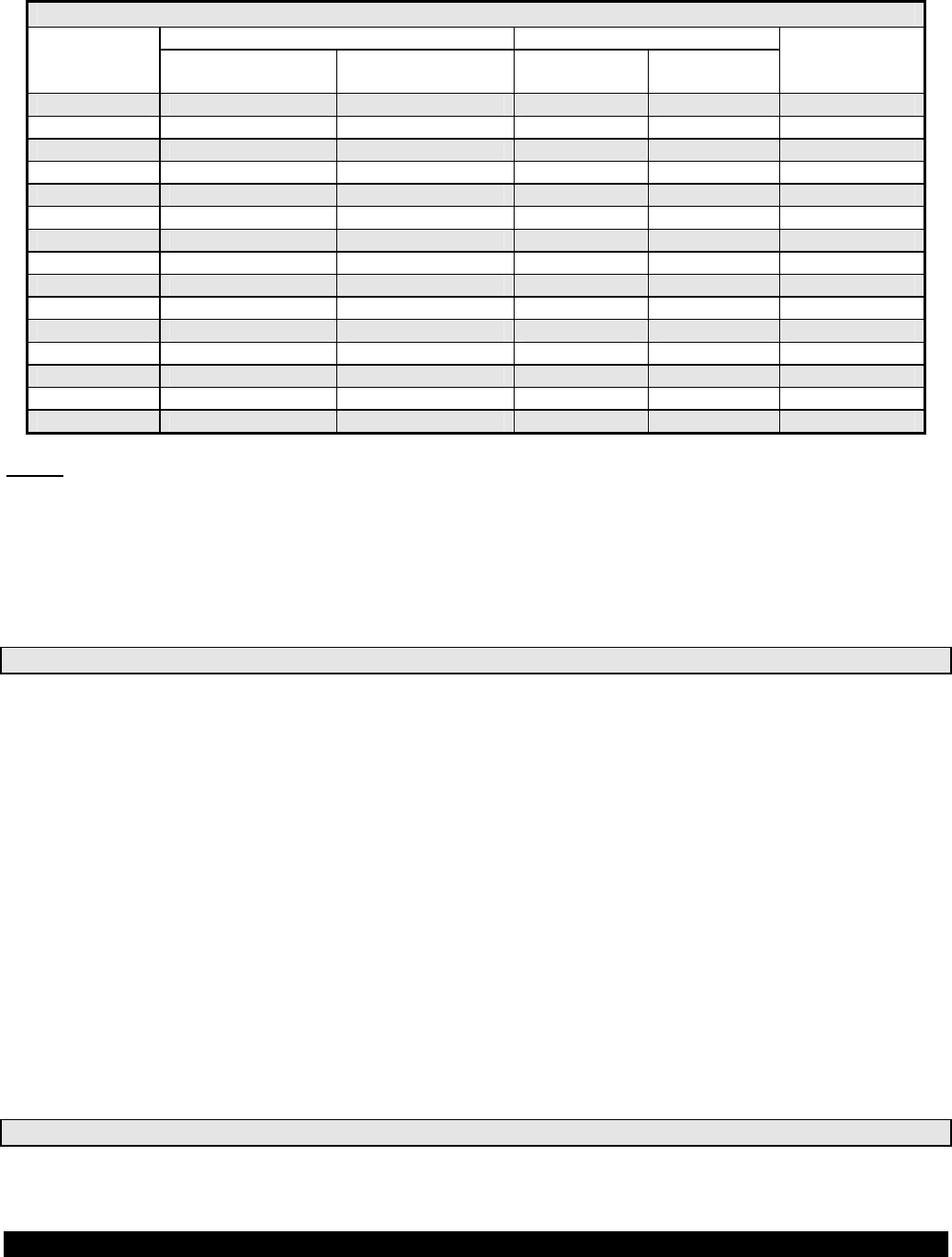

Cooling Water Requirements

MODEL # HEAT TO COOLING WATER KW INPUT (4)

COOLING

WATER

AMBIENT (1) GPM (2) GPM (3)

D-400-W 23682 1780 4.7 1.9 1.95

D-500-W 33894 2550 6.8 2.7 2.6

D-600-W 37250 3650 7.5 3.0 2.92

D-800-W 52859 3980 10.6 4.3 4.22

D-1000-W 66150 5360 13.2 5.3 4.8

D-1600-W 90845 7366 18 7.3 6.82

D-2000-W 128646 10431 26 10.3 9.4

D-2500-W 135330 10185 27 10.8 9.4

D-3200-W 186550 14040 37 15 12.9

D-4000-W 206480 15540 41 16.5 14.2

D-5000-W 268075 20175 54 21.5 18.9

D-6250-W 367117 27632 73.4 29.4 28.9

D-7500-W 472231 35544 78.0 31.4 34.5

D-8000-W 412960 31080 82.0 33.0 38.7

D-10000-W 536150 40350 108 43.0 41.8

Notes:

(1) Approximately 7% of the total heat load is rejected to ambient air, the balance to the

water-cooled condenser.

(2) Based on cooling tower water 85°F to condenser, 95°F out of condenser, 78°F ambient wet

bulb temperature.

(3) Based on water into condenser @ 60°F (city water). Water temperature out of condenser, 85°F.

(4) Kilowatt (Power) consumption by the refrigeration compressor motor.

(5) Heat amounts are expressed in B.T.U.H.

M. MAINTENANCE

A properly installed Air/Tak refrigerated air dryer requires very little maintenance to provide years of trouble-free

service. A very simple routine maintenance program is all that is required. This program will consist of three (3)

check points:

1. Drain Valve(s): Inspect and clean the Drain Valve(s) on a periodic basis.

2. Refrigeration Condenser: Inspect the refrigeration condenser for lint and dirt.

a) The refrigeration condenser should be checked for lint or dirt monthly in a clean environment

and more often in a dirty environment. If the condenser is found to be dirty, it must be cleaned

with low pressure dry air.

Inspect condenser fans; i.e., bent or broken blades, and for free rotation.

a) Check condenser fan(s), brackets and on motor shaft for tightness.

3. Check refrigerant lines for oily connections and vibration in lines. Check wiring for loose and broken

wire ties. Check refrigerant sightglass for moisture. (See Troubleshooting Guide).

N. INSTALLATION OF REMOTE CONDENSER (OPTIONAL)

During installation of a Remote Condenser option, Air/Tak recommends the use of check valves or P-traps at

condenser inlet and outlet.

TROUBLESHOOTING GUIDE