© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Maintenance

41

F232102

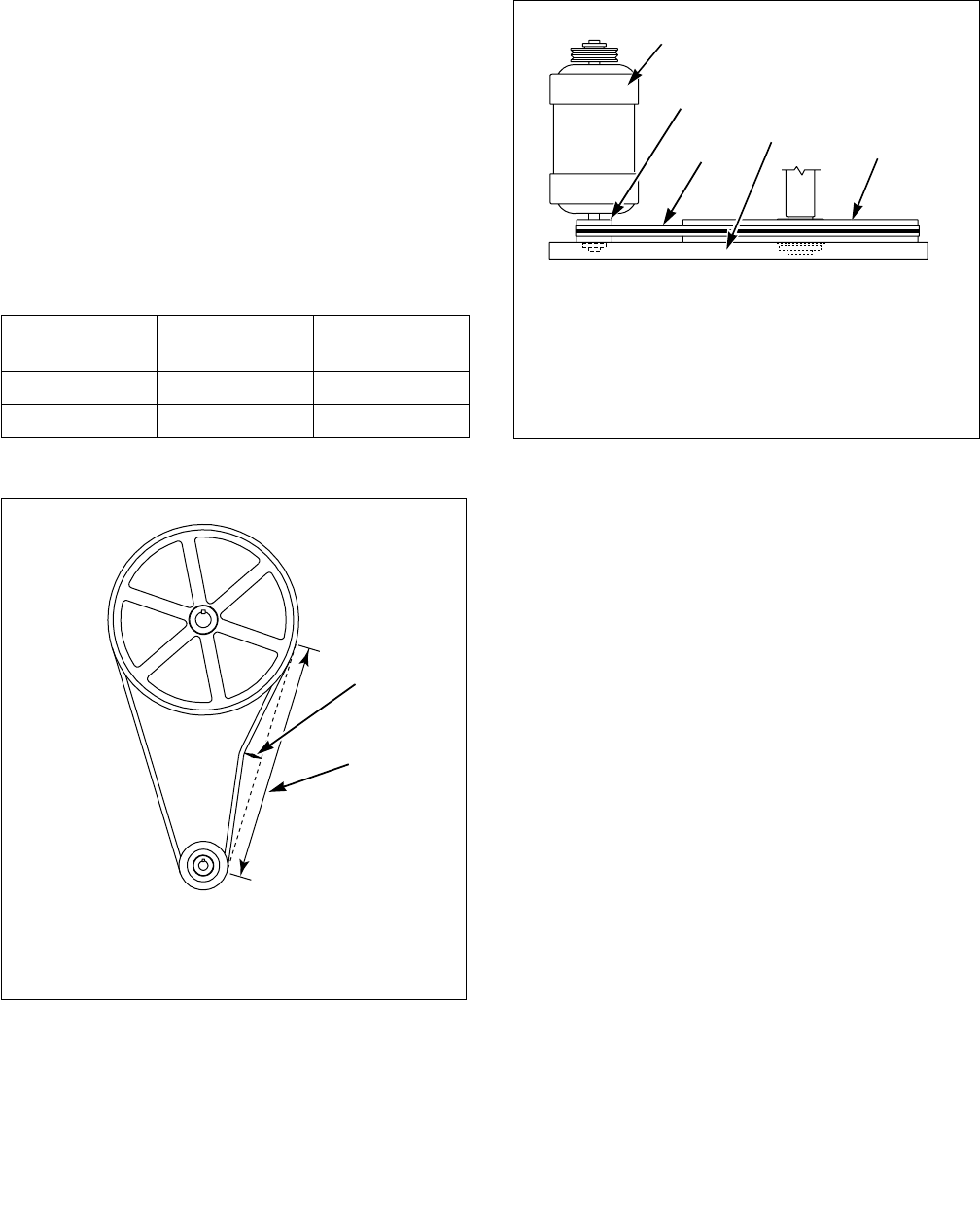

3. Use the following procedures to determine if

V-belts require replacement or adjustment. Call

a qualified service technician in either case.

a. Check V-belts for uneven wear and frayed

edges.

b. After disconnecting power to the machine and

removing all panels necessary for access to

the drive belt, use the following method to

verify that V-belts are properly tensioned.

Refer to Figure 25. Belt deflection should be

measured as close to the center of the span

length as possible. A set force should be

applied in the center of the span length, as

specified in Table 11. Belt tension is adjusted

by turning the setscrew on the idler pulley.

Turning the screw clockwise tightens the belt,

and vice versa.

Figure 25

c. Verify that V-belts are properly aligned by

checking pulley alignment. Place a

straightedge across both pulley faces. The

straightedge should make contact with the

pulleys in four places. Refer to Figure 26.

Figure 26

4. Remove back panel and check overflow hose and

drain hose for leaks.

5. Clean inlet hose filter screen.

a. Turn water off and allow valve to cool, if

necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace

if worn or damaged.

6. Unlock the hinged lid and check the supply

dispenser hoses and hose connections.

7. Tighten motor mounting bolt locknuts and

bearing bolt locknuts, if necessary.

8. Use compressed air to clean lint from motor.

9. Clean interior of machine, both basket and shell,

by wiping with a water-soaked sponge or cloth.

10. Use compressed air to ensure that all electrical

components are free of moisture and dust.

Machine

Capacity Deflection

Force

Applied

135 pound 0.730

in. 11.25 lbs.

250 pound 0.655

in. 16.85 lbs.

Table 11

CFS220N

1 Deflection

2 Span Length

1

2

P045I

1 Motor

2 Drive Pulley

3 Belt

4 Straightedge

5 Driven Pulley

1

2

3

4

5