25

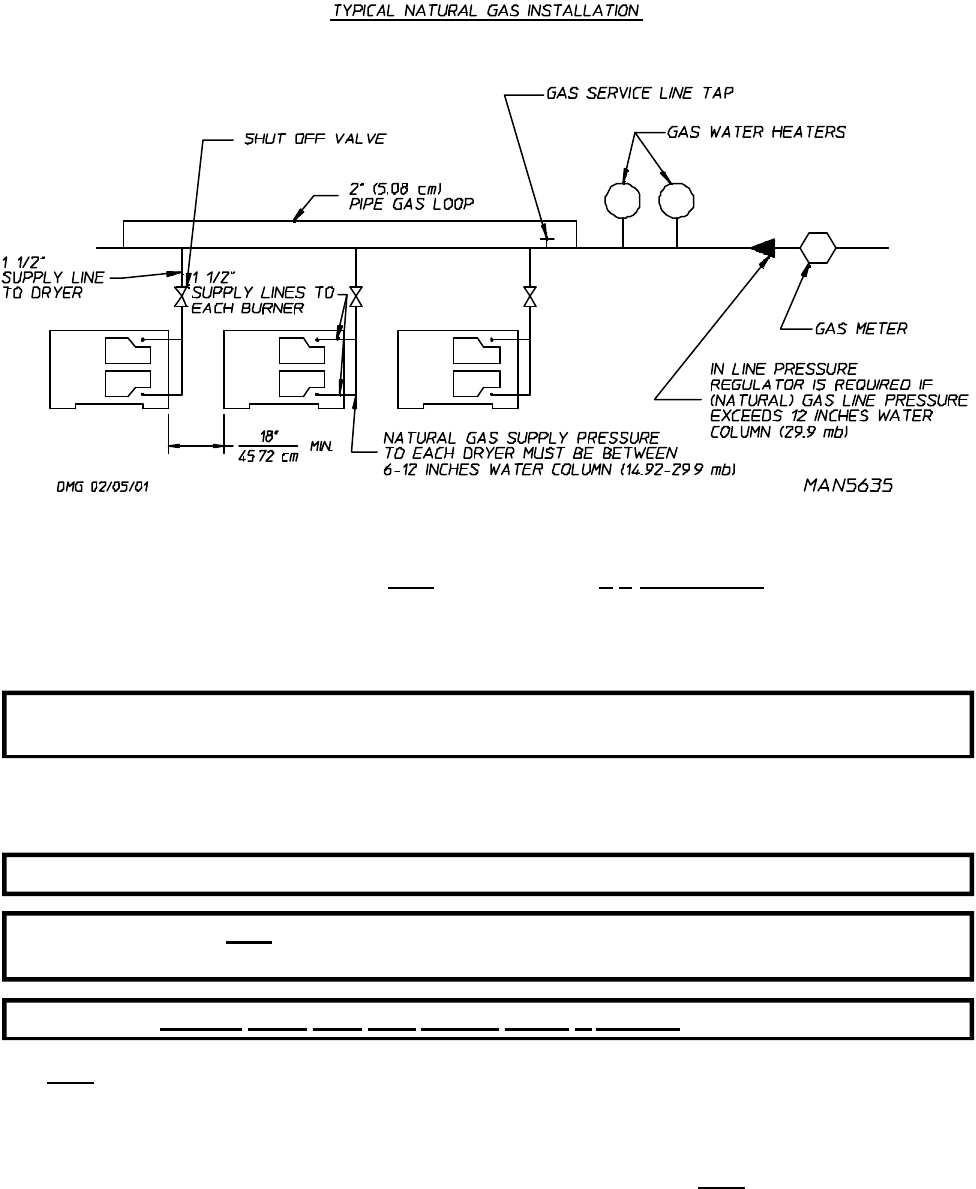

Consistent gas pressure is essential at ALL gas connections. It is recommended that a 2-inch (5.08 cm)

pipe gas loop be installed in the supply line servicing a bank of dryers. An in-line pressure regulator must be

installed in the gas supply line (header) if the (natural) gas pressure exceeds 12.0 inches (29.9 mb) of water

column (W.C.) pressure.

IMPORTANT: A water column pressure of 3.5 inches (8.7 mb) for natural gas is required at the gas

valve pressure tap of each dryer for proper and safe operation.

A 1/8-inch N.P.T. plugged tap, accessible for a test gauge connection, must be installed in the main gas

supply line immediately upstream of each dryer.

IMPORTANT: Pipe joint compounds that resist the action of natural gas must be used.

IMPORTANT: Test ALL connections for leaks by brushing on a soapy water solution (liquid

detergent works well).

WARNING: NEVER TEST FOR GAS LEAKS WITH A FLAME!!!

ALL components/materials must conform to National Fuel Gas Code Specifications ANSI Z223.1-LATEST

EDITION, or in Canada, CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGA-B149.2-M91 or

LATEST EDITION (for General Installation and Gas Plumbing), as well as local codes and ordinances and

must be done by a qualified professional. It is important that gas pressure regulators meet applicable

pressure requirements, and that gas meters be rated for the total amount of ALL the appliance BTUs being

supplied.