55

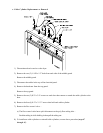

I. Control Electrical System

CAUTION: When servicing the HIGH VOLTAGE section of the dryer, the ELECTRIC

SERVICE MUST BE DISABLED. THE "EMERGENCY STOP" BUTTON

DOES NOT DISABLE THE HIGH VOLTAGE TO THE DRYER.

1. Control Electrical System Description

a. 3-Phase (3ø) Electrical Power

The 3-phase (3ø) electrical power for the dryer enters the dryer through the power distribution block

located in the dryer base electrical box. It is then distributed to the blower (impellor and fan) motor, drive

(tumbler and basket) motor, and control circuits.

1) Blower (squirrel cage fan) Motor

The blower (impellor and fan) motor circuit consists of a blower motor thermal magnetic overload.

The overload current is adjustable by a dial located on the face of the overload. (Refer to the

electrical specification diagram for correct current setting.)

Attached to the thermal magnetic starter is an auxiliary contact used to sense an overload trip. This

produces a safety error so the dryer service is disabled (the dryer will not start).

In series with the thermal magnetic overload is the blower motor contactor. This device enables the

supply voltage to reach the blower (impellor and fan) motor. The blower motor contactor is controlled

by the Phase 5 microprocessor controller (computer). When 24 VAC is applied to coil A1-A2, the

contactor closes and enables the circuit.

The blower (impellor and fan) motor used for ADG-200 gas model dryers is 7-1/2 HP (horsepower)

and for ADS-200 steam model dryers is 15 HP (horsepower) . The motor wiring configuration is

dependent on the specific voltage of the dryer. When wiring the motor, refer to the motor nameplate.

2) Drive (tumbler/basket) Motor

The drive (tumbler and basket) motor converts the 3-phase (3ø) power source entering the drive

motor thermal magnetic overload. The overload current is adjustable by a dial located on the face of

the overload. (Refer to the electrical specification diagram for correct current setting.) In this

circuit, the drive motor contactor follows the thermal magnetic overload.

The drive motor has two (2) separate sets of coils and two (2) separate sets of contacts. One (1) of

these sets is for forward tumbler (basket and drum) rotation and the other for reverse tumbler (basket

and drum) rotation. The thermal magnetic overloads and the contactors are located in the left hand

electrical cabinet. The direction of the drive motor is determined by the phases going into the motor

(i.e., in a reverse direction phase, L1 and L2 are switched). When viewing this contactor, the left

hand block connections are for the forward rotation direction (clockwise [CW]) when viewed from

the front of the dryer.

The drive (tumbler and basket) motor is a 3 HP (horsepower) motor. Refer to the motor nameplate

for specific terminal box wiring.