18

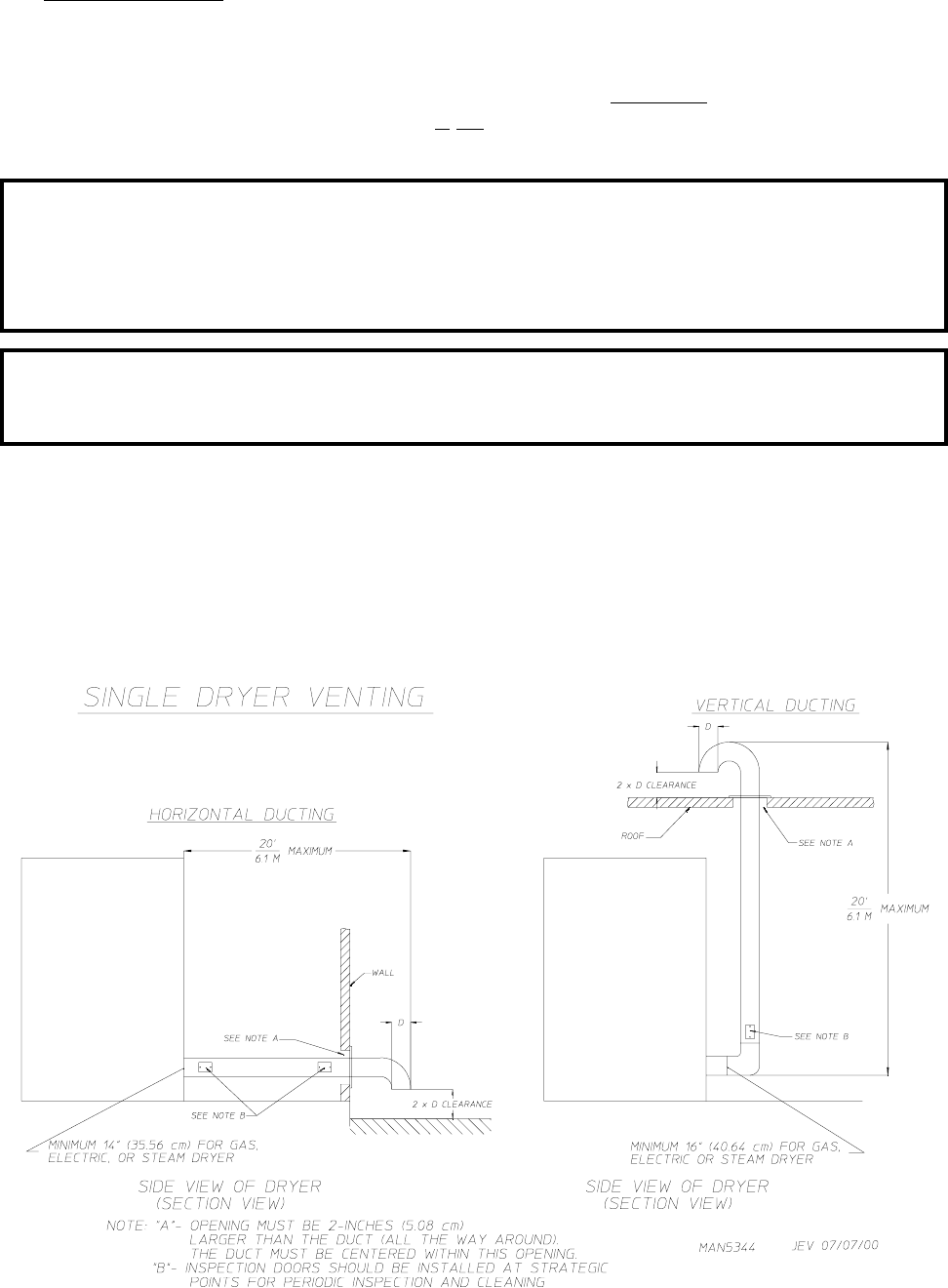

2. Single Dryer Venting

When possible, it is suggested to provide a separate exhaust duct for each dryer. The exhaust duct should

be laid out in such a way that the ductwork travels as directly as possible to the outdoors with as few turns

as possible. It is suggested that the use of 90° turns in ducting

be avoided; use 30° and/or 45° angles

instead. The shape of the exhaust ductwork

is not critical so long as the minimum cross section area is

provided.

IMPORTANT: Minimum duct size for a gas, electric, or steam dryer with a vertical run and not more

than three (3) elbows (including dryer connection and outside outlets) is 16-inches

(40.64 cm) for a round duct or 14-1/2” by 14-1/2” (36.83 cm by 36.83 cm) for a

square duct. DUCT SIZE MUST NOT BE REDUCED ANYWHERE

DOWNSTREAM OF DRYER.

IMPORTANT: Exhaust back pressure measured by a manometer at each basket (tumbler) exhaust

duct area must be no less than 0 and must not exceed 0.3 inches (0.74 mb) of water

column (W.C.).

It is suggested that the ductwork from each dryer (minimum 14-inches [35.56 cm]) not exceed 20 feet

(6.09 meters) with no more than three (3) elbows (including dryer connections and outside exhaust outlets).

If the ductwork exceeds 20 feet (6.09 meters) or has numerous elbows, the cross section area of the

ductwork must be increased in proportion to the length and number of elbows in it. In calculating duct size,

the cross section area of a square or rectangular duct must be increased by twenty percent (20%) for

each additional 20 feet (6.09 meters). The diameter of a round exhaust duct should be increased ten

percent (10%) for each additional 15 feet (4.57 meters). Each 14-inch (35.56 cm) 90° elbow is equivalent

to 30 feet (9.14 meters) and each 16-inch (40.64 cm) 90° elbow is equivalent to 36 feet (10.97 meters).